Basic Information of Steel Structure Building

- 15 Aug 2020

- steel structure

1. Overview: Steel Structure Building

1.1 Main steel structure material;

1.2 Enclosure structure material;

1.3 Fittings(Climbing ladders, overhauling walkways, fans, doors and windows, etc.)

2. Classification of steel structure materials

2.1 Classified by processing method of steel:

(1)Hot rolled steel plate;

(2)Cold rolled steel plate;

2.2 Classified by shape of steel:

(1)striped steel plate;

(2)Checkered plate;

(3)profiled steel;

(4)special shaped steel,etc.

2.3 Classified by different surface treatment methods of steel:

(1)Steel plate or coil;

(2)galvanized steel plate;

(3)Color coated steel plate, etc..

2.4 Classified by thickness of steel plate:

(1)Thin plate;

(2)Medium plate

(3)Thick plate;

(4)Extra-thick plates

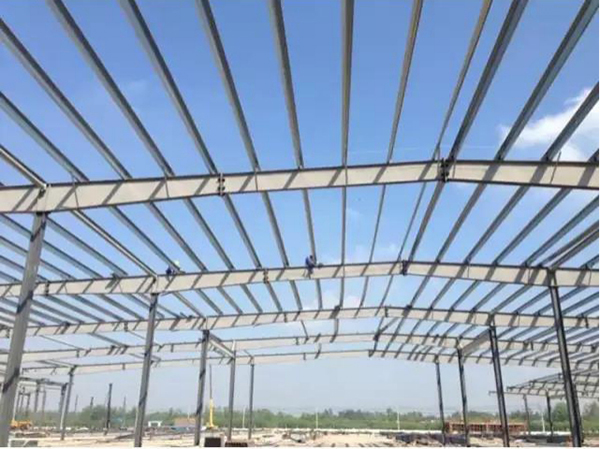

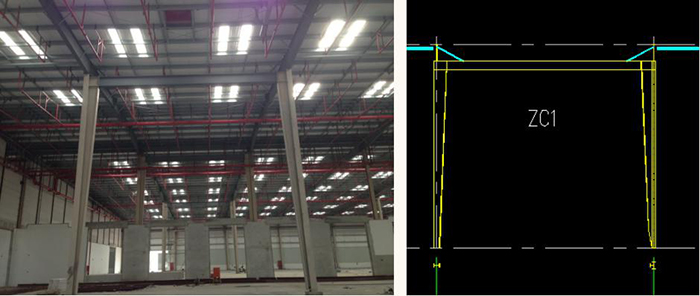

3. Portal frame system-classification

According to the different parts of the portal frame light steel structure factory, it is divided as follows:

①Main steel structure: anchor bolts, steel columns, steel beams, Mezzanine beams, roof purlins, roof horizontal supports, roof pipe supports, corner supports, inter-purlin supports, diagonal rods, wall vertical supports, wall purlins, etc.

② Enclosure structure: roof panel, wall panel, sandwich panel, curtain wall panel, trim, etc.

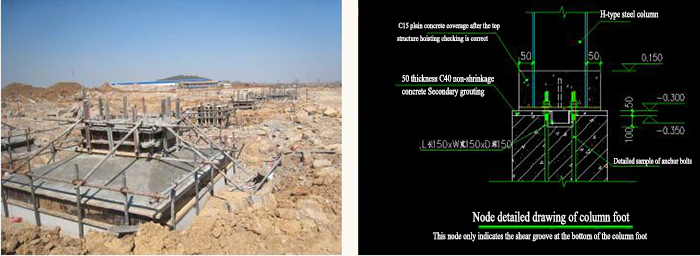

3.1 Main Steel Structure——anchor bolt

The anchor bolts are generally made of Q235B round steel material, and the supporting components are 3 nuts, 1 gasket and 1 square pad. 3 nuts play different roles: leveling, tightening, and anti-loosening. The shear key at the bottom of the column generally uses No. 10 channel steel, and a 50mm secondary grouting layer is reserved between the column bottom plate and the foundation, and no shrinkage concrete is used. The foot of the column is 150mm in height. Pay attention to the relative position of the axis line when installing the anchor bolts.

3.2 Main steel structure——steel column, steel beam

Cutting and hole making construction H-type Automatic submerged arc welding

Component section size inspection Weld bead flaw detection

The main material of the steel plate that composes the steel column and steel beam is Q235B or Q345B, which is processed by the factory through cutting, drilling, assembly, welding, straightening, shot blasting, painting and other procedures. They are the main stress-bearing components of light steel structures, and the quality of production and installation directly affects the engineering quality and safety of the workshop. Therefore, the following content needs to be strictly controlled: raw materials, production accuracy, installation accuracy, etc.

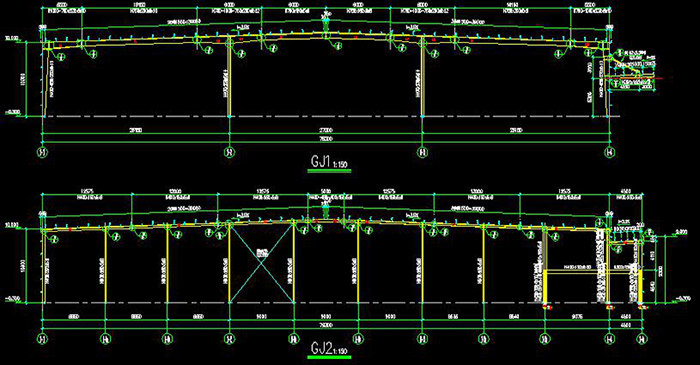

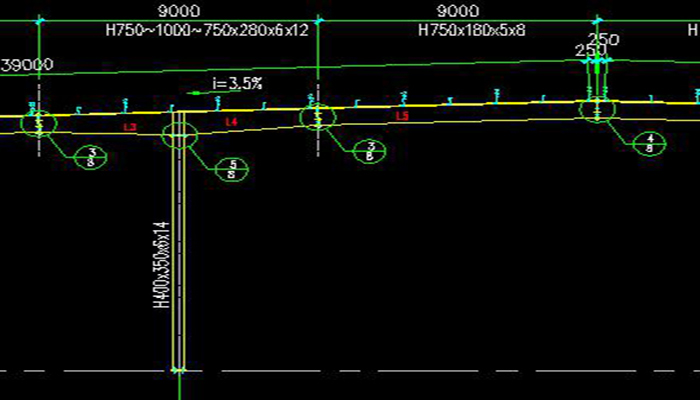

1. H-type steel column:H400*350*5*14

Web plate height 400mm thickness 5mm,flange width 350mm thickness 14mm.

H-type steel beam:

2. H(750~1000~750)*280*6*12

The web plate height is a variable section750-1000-750 thickness 6mm,flange width 280mm thickness 12mm.

3. i=3.5% is roof slope.

4. 3/8 3 represent node number,8 represent the drawing number of node.

3.3 Main steel structure ——Mezzanine beam

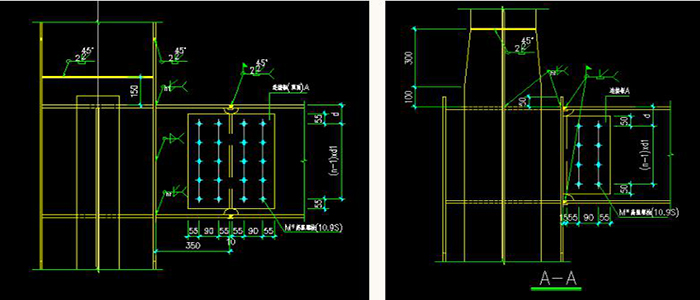

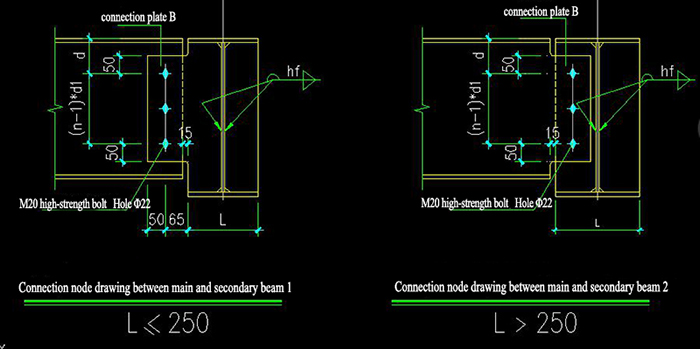

Mezzanine beams generally belong to the frame structure system. The main beam is rigidly connected to the steel column (secondary welding), and the secondary beam is hinged to the main beam (high-strength bolt connection).

Meaning of welding symbols: single-sided (double-sided) fillet welds, equal-strength welds, full penetration welds, etc. On-site secondary full penetration welds require third-party sampling inspection.

The main beam and the steel column corbel are rigidly connected The main beam and steel column flange plate are rigidly connected

secondary beam and main beam hinged connection joint

The torque value of high-strength bolt construction must meet the experimental data requirements, and the final tightening should not be omitted.

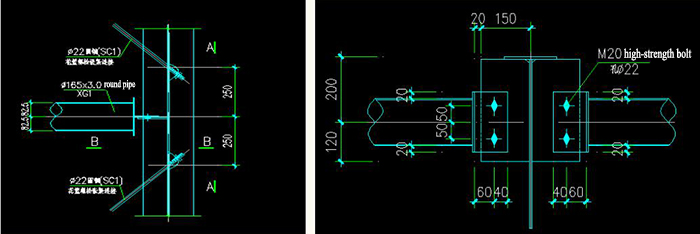

3.4 Main steel structure ——supporting system

Column top tie rods generally use Q235B seamless steel pipe or welded steel pipe, and the connection method is high-strength bolt connection

The horizontal support of the roof and the vertical support of the wall generally adopt Q235B round steel, which is generally tensioned by flower basket bolts.

Roof horizontal support and tie rod node diagram Double-sided roof tie rod node diagram

Note: The support is the main force transmission structure of the steel structure and must be installed in strict accordance with the requirements of the drawing. The appropriate tension is generally controlled at 1/700L. Round pipe section size, mechanical properties, gasket, nut.

In logistics warehousing projects, it is generally forbidden to set up scissor supports at the center axis location, and they are usually designed as portal supports.

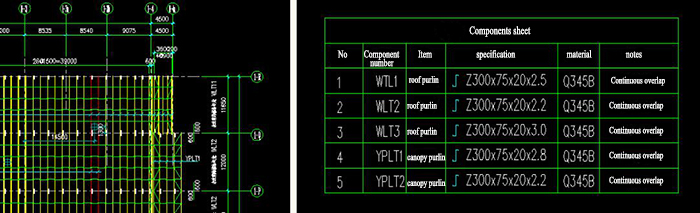

3.5 Main steel structure——Roof purlin、wall purlin

Galvanized purlin: generally use Q345B steel, hot-dip galvanized coil, the galvanizing quantity of double sides should be not less than 275g/m2, factory processed and pre-punched.

Paint purlin: Q235B steel is generally used. The surface should be rust-removal, and the thickness of the anti-rust paint is generally not less than 60um, which is factory processed and pre-punched.

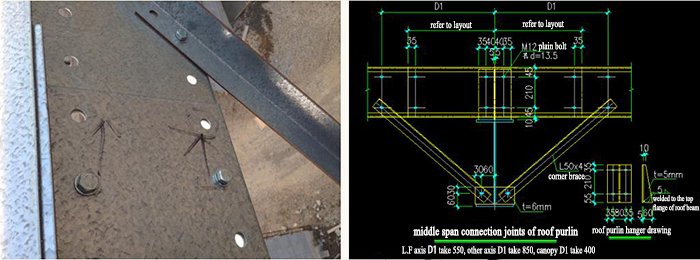

Z-shaped roof purlins are generally designed with continuous beams. Installation precautions: the same length and different thickness should not be mixed. The materials should be rainproof when they arrive at construction site, and they should be installed in time since they are easy to rust when stacked for a long time.

3.6 Main steel structure ——corner brace

Classification: roof corner brace, wall corner brace. Function: Ensure the out-of-plane stability of roof beams and steel columns, reduce the out-of-plane calculation length, and play a key role in structural safety. GLP projects generally use Q235B, hot-dip galvanized coils, and the double-sided galvanizing amount is not less than 275g/m2.

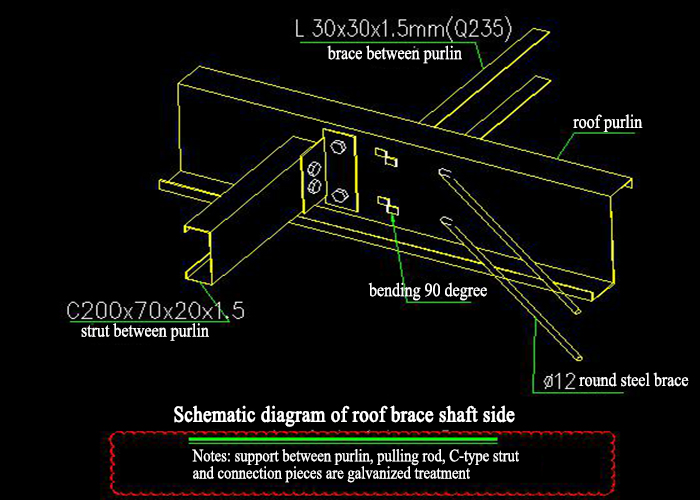

3.7 Main steel structure——Supports between purlins, diagonal rods, secondary purlins

The roof purlin support, 12-diameter tie rod, secondary -purlin, C-type support, cornice adjustment tie rod, etc. are all made of hot-dip galvanized coils, with double-sided galvanizing amount not less than 275g/m2, factory processed and pre-punched.

The roof secondary -purlin Q235B hot-dip galvanized coil , and the connection way is fixed by self-drilling nails.

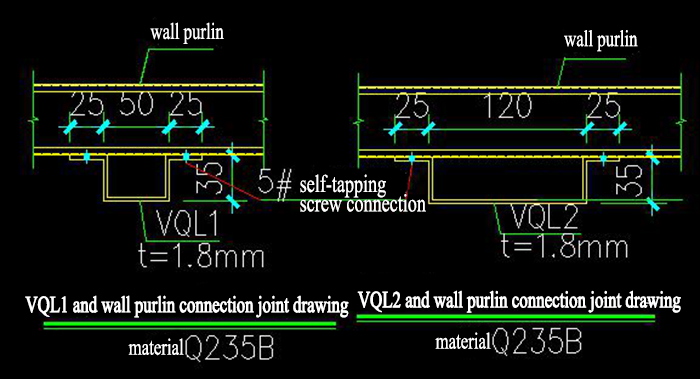

The walls secondary Q235B hot-dip galvanized coil, and connection way is fixed by expansion bolts or self-drilling nails.

The roof purlin supports L30*1.5 galvanized angle steel, and the connection method is 90° bend at the end.

The wall secondary purlin is made of Q235B hot-dip galvanized coil, and a wide secondary purlin is set at the overlapping position of the horizontal panel.

3.8 Main steel structure——main accessories

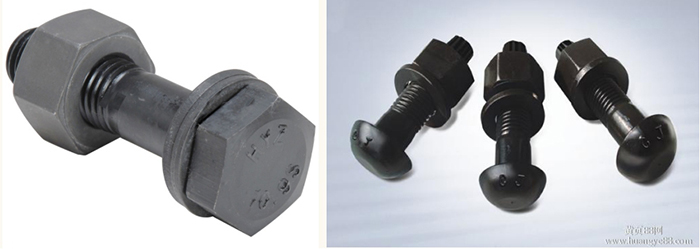

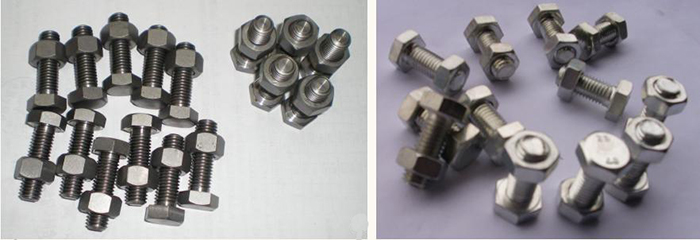

3.8.1 High strength bolt A set of high-strength bolts comes standard with: 1 screw rod, 1 nut, and 2 washers. The surface is generally treated with blackening and rust prevention.

Main specifications:M12、M16、M20、M22、M24、M27、M30

Large hexagon high-strength bolts Torsion shear type high strength bolt

3.8.2 Plain bolt

The surface of ordinary bolts is generally hot-dip galvanized. A set of ordinary bolts includes: 1 screw rod, 1 nut, and 2 washers. Light steel structure generally adopts M12.

Note: Whether it is missing or fastened; whether the installation position is correct.

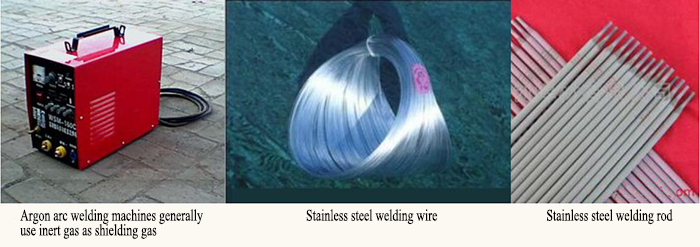

3.9 Main steel structure——welding material

Main specifications of welding rod: diameter 3.2, 4, 5 (mm); classification of construction steel structure welding rod: low hydrogen type E50 is mainly used for welding of Q345 steel plate; ordinary type E43 is mainly used for welding between Q345 and Q235 steel plates, and Q235 steel plate welding.

Main specifications of welding wire: diameter 0.8~1.6mm; mainly equipped with carbon dioxide shielding gas.

Submerged arc welding

Note: weld beam forming quality, undercut, reinforcement, backing plate size.

Submerged arc welding machine and flux

Mainly used for the welding of light steel structure stainless steel inner gutter; Note: The welding position of the inner gutter baffle, the flange of the inner gutter is fully welded, and the stainless steel gutter whose thickness is less than 2mm is generally welded by welding wire.

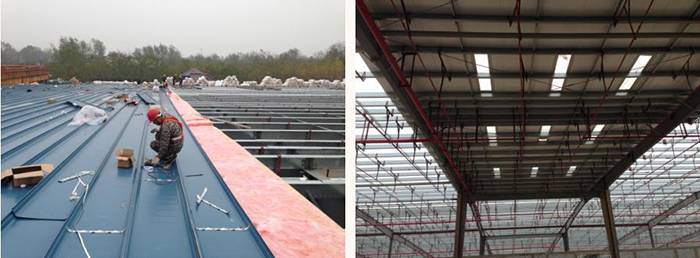

3.10 Enclosure structure——Roof panel

There are many types of roof panels, and each company is not the same. The attached picture shows Butler MR24 roof panels and Oppen 464 panels.

Roof panels are generally divided into two categories: 1. Aluminum-zinc-plated natural color panels; 2. Color-coated panels

GLP has the following technical requirements for roof panels:

1. The roof panel is made of galvanized steel with a thickness of not less than 0.6mm, the amount of galvanized steel is not less than 165g/m2, and the material yield strength is not less than 345Mpa;

2. The roof slope is 3.5% (should ensure that the maximum clear height in the warehouse does not exceed 12 meters), adopts 360-degree vertical seam and lock seam, pre-coated sealant in the seam, horizontal lap joint sealing, reliable structure.

Note: The thickness of the roof panel should be clearly whether it is the thickness of the substrate or includes the thickness of the paint coating? Is sealant pre-applied to the joints of roof panels? Roof panels overlap waterproof nodes and so on.

3.11 Enclosure structure——insulation Cotton

Technical requirements for roof insulation cotton:

The density is 12kg/m3, imported polypropylene veneer (WMP-VR); the thickness is determined according to the local climate conditions. (The practice in East China, Southern and Central and Western Regions: the thickness of thermal insulation cotton is 75mm. The practice in the Northern Region: the thickness of thermal insulation cotton is 100mm.)

Precautions for insulation cotton construction: insulation cotton veneer (reinforced) strength, insulation cotton installation flatness, insulation cotton horizontal and vertical overlap treatment method, skylight panel fan opening insulation cotton cutting quality, inner gutter cornice insulation cotton treatment method, etc.

3.12 Enclosure——Roof skylight panel

3.12.1 The material strength and durability of roof skylight panels should meet the requirements of building functions, with a thickness of not less than 1.5mm, anti-ultraviolet performance of more than 99%, aging resistance, light transmittance rate should be 70%, heat insulation performance and easy to melt Performance (It can be melted and does not produce drops when it is above 80℃).

3.12.2 The joints between roof skylight panels and metal roof panels must adopt structural measures to ensure airtightness and water closure. No waterproof coiled materials or waterproof coatings should be used on their surfaces. At the same time, consideration should be given to avoiding shear stress caused by differences in expansion coefficients.

3.12.3 The roof skylight panel adopts the point arrangement form, and should avoid being in the same position with the fire sprinkler. The proportion of the roof skylight panel should meet the requirements of the construction profession, generally 3%.

3.12.4 Roof skylight panel are divided into 2 categories: 1. Insulation skylight panels (double-layer); 2. Non-insulation skylight panels (single layer); selected reasonably according to the temperature change, design requirements, and process requirements of the project location.

3.12.5 Precautions for the installation of skylight panels: uniform and reasonable layout, overlapping treatment methods, sealing treatment nodes, etc.

3.13 Enclosure structure-----roof accessories

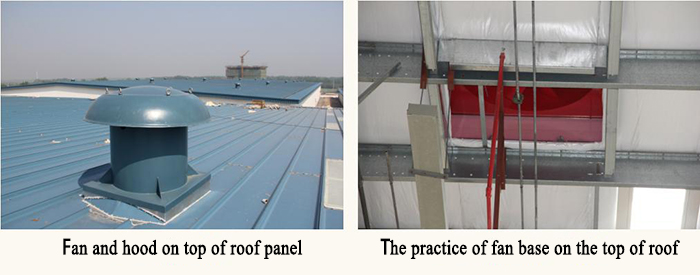

Roof panel connection pieces; self-drilling screw; metal plugs; rubber plugs; roof fan openings; outdoor ladders, etc.

3.14 Enclosure structure——external wall panel

Regulations for GLP exterior wall panels

1. Horizontal placed large corrugated color steel plate is preferred for steel structure wall enclosure structure. Vertical aluminum plate/large corrugated plate can be used in dusty areas.

2. The exterior wall panel adopts aluminum zinc color steel plate with a thickness of not less than 0.5mm, the amount of galvanized zinc is not less than 150g/m2, and the yield strength of the material is not less than 345Mpa; the surface adopts high durability coating (HDP), which requires there will be no chalking on the outer surface of the color steel plate during the 10 year. The color tone is determined by the site. Generally, silver gray or similar colors are used for horizontal placed panel; the color number and plate type of each contractor shall be determined by providing samples.

3. When the external wall panels are horizontally placed, the main vertical seam should be set, and the thermal insulation cotton should be set between the vertical reinforcement and the horizontal wall reinforcement; when installing the wall panels, attention must be paid to the positioning and alignment of the wall panels, so that they are straight and fit.

4. There are no creases, dents or damages on the wall panel and its flashing edges;

5. The surface coatings of all kinds of edging and flashing boards are consistent with the wall panels or roof panels at the location;

6. A flashing board should be installed at the bottom of the metal wall panel;

7. The color of the exposed screws on the external wall is the same as that of the external wall panel;

8. The secondary structural components should not be exposed on the external surface of the building;

9. The color of external wall edge, the external gutter and water downpipe should adopts the color of the exterior wall panel or black.

3.15 Enclosure structure-external sandwich wall panel

Regulations for GLP external wall sandwich panels

1. Laying method: usually adopts horizontal arrangement; panel width 800mm, length no more than 9m, horizontal overlap, gap 10~12mm, meeting waterproof requirements.

2. The external plate is made of aluminum zinc color steel plate with a thickness of not less than 0.5mm, the amount of aluminum-zinc is not less than 150g/m2, and the material yield strength is not less than 345Mpa; the internal plate is made of aluminum-zinc color steel plate with a thickness of not less than 0.4mm. The front coating of the external panel is a PVDF coating,while the front coating of the internal board is a PE coating, the thermal conductivity of rock wool is λ≤0.043 W/(mK), the density of rock wool is 120 Kg/m3, and the combustion performance class is Class A non-combustible.

3. The surface form of the external steel plate is embossed with orange peel, and the color is gray and corporate green. Samples and layout drawings are sent to HQ Design for confirmation before purchasing.

4. The thickness of the sandwich panel is 50~100mm; the thickness needs to meet the thermal calculation under the local climatic conditions.

5. The specially designed sandwich panel laps and sockets need to be equipped with sealing strips, anti-siphon grooves and other waterproof components to meet the waterproof requirements; the connection of the sandwich panels is hidden nailed type, the screws are not exposed, which can increase the service lifetime.

3.16 Enclosure structure——internal wall panel

Use aluminized zinc color steel plate with a thickness of not less than 0.4mm, the amount of aluminized zinc is not less than 70g/㎡, the yield strength of the material is not less than 345Mpa, the surface is coated with polyester (PE); the color tone is off-white; Lay lining board from the skirt wall to the bottom of roof panel or below 4 meters elevation.

4. Accessories——Fireproof coating

4.1 Accessories ——fire-proof coating

Fire resistance limit: 2.0 hours for steel pillars in the storage area, 1.5 hours for steel beams in the storage area, and 1.0 hours for roof purlins in the storage area. 2.5 hours for dispatch indoor steel columns and 2.0 hours for mezzanine beam.

Fire-resistant coatings are divided into oil-based fire-proof coatings and water-based fire-proof coatings. The project can also be divided into think type or thick type, oil-based or water-based type, which should be determined according to the design drawing and local fire department requirements.

Thick fire-proof coating on steel columns

4.2 Accessories——Stainless steel gutter

1.5mm thickness stainless inner gutter overlap treatment 3.0mm thickness siphon stainless steel inner gutter

5. Steel structure engineering inspection project

5.1 Anchor bolt sampling inspection; 2 pieces of each specification, retest: compressive and tensile

5.2 Retest of high-strength bolts: 8 of each specification, retest: torque value

5.3 Retest of high-strength bolt components: a set of anti-slip components, retest: anti-slip coefficient

5.4 Steel material retest: 2 test pieces of each specification, retest: compressive and tensile

5.5 Non-destructive inspection of welds: 100% inspection of factory components, secondary penetration on-site ,Weld spot 20% random inspection

5.6 House integrity inspection (required by some regions)

5.7 Fireproof coating inspection

5.8 Rock wool and glass wool energy-saving testing and fire-proof testing

6. Steel structure management

Steel structure management suggestions for logistics warehousing projects:

1. Steel structure management mode;

2. Steel structure production, installation and enclosure structure subcontract management;

3. Supplier management (material suppliers, subcontractors, etc.);

4. Cost analysis and management;

5. Steel structure design and detailed drawing management;

6. management of refined materials;

7. Others.