Classification of steel structure materials

- 26 Aug 2020

- steel structure

1. Classification according to steel processing methods:

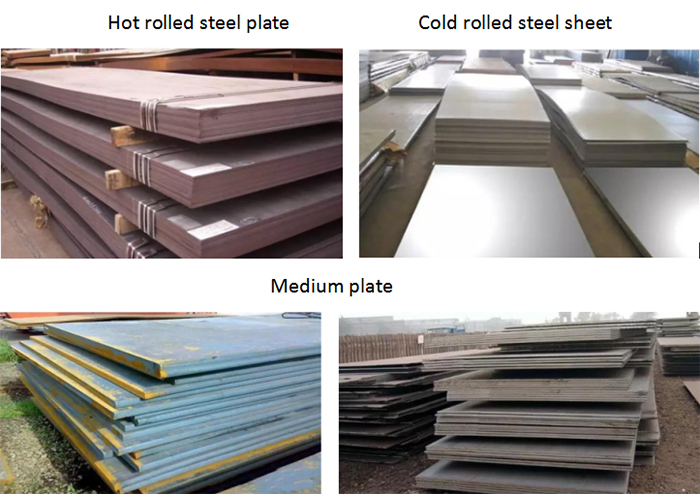

(1) Hot rolled steel plate;

(2)Cold rolled steel sheet;

2. Classification according to steel shape:

(1) With steel plate;

(2) Pattern plate;

(3) Section steel;

(4)Special shaped steel, etc.

3. Classification according to different surface treatment methods of steel:

(1) Steel plate or rolled plate;

(2) Galvanized steel sheet;

(3) Color coated steel plate, etc.

4. According to the thickness of steel plate:

(1) Thin plate;

(2) Medium plate;

(3) Thick plate;

(4)Extra heavy plate.

5. Thin plate refers to steel plate with thickness less than 4mm. In practical work, steel plate with thickness greater than 4mm less than or equal to 20mm is called medium plate, steel plate with thickness greater than 20mm to 60mm is called thick plate, and steel plate with thickness greater than 60mm belongs to extra thick plate (shipbuilding, warship, etc.).

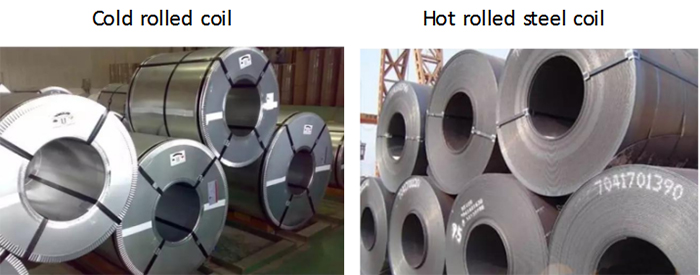

6. Steel: hot rolling and cold rolling

Hot rolling takes slab (mainly continuous casting slab) as raw material, which is made by roughing mill and finishing mill after heating. The hot strip from the last finishing mill is cooled to the set temperature by laminar flow, and then rolled into steel strip coil by coiler. After cooling, the steel strip coil can meet different needs of users, Through different finishing lines (leveling, straightening, cross cutting or longitudinal cutting, inspection, weighing, packaging and marking, etc.), the products are made of steel plate, flat roll and longitudinal cutting steel strip.

Cold rolling is based on the hot-rolled coil processing and rolling, generally speaking, it is hot rolling pickling cold rolling process. Cold rolling is processed from hot-rolled plate at room temperature. Although rolling will also make the steel plate warm in the process, it is still called cold rolling

7. Steel plate material: mainly including Q235 and Q345. Q is the yield strength, Q235 is the yield strength above 235 MPa, B in Q235B is the grade of impact test, which is divided into a, B, C, D, where a is not subject to impact test, B is impact test at 20 ℃ room temperature, C is impact test at 0 ℃ and D is impact test at - 20 ℃ low temperature. Q345 belongs to low alloy steel (C < 0.2%).

The thickness of steel plate is generally 6-120mm, of which the price of 6 mm, 8 mm, 10 mm and 12 mm plate decreases in turn, among which the price of 6 mm medium plate is the most expensive; 14-30 mm is the common specification, and the price is at the same level; 32-49mm belongs to the thick plate series, the price is at the same level, slightly higher than the common specification plate; 50-120mm belongs to ultra thick plate series, and the price of 50-90mm plate is at the same level, With the increase of thickness, the price of 90mm and above plate will increase. The representative specification of medium and heavy plate is 20 mm.

The width of steel plate is generally 700, 750, 800, 850, 900, 950, 1000, 1100, 1250, 1400, 1420, 1500, 1600, 1700, 1800, 1900, 2000, 2100, 2200. The length of steel plate is generally customized according to the demand, and the normal length is 12 meters.

8. Hot rolled coil

The general thickness of hot rolled coil (in the form of plate or coil) is 2.0-13.5mm, of which the price of 2.0-3.0mm hot coil gradually decreases from thin to thick; the price of 3.1-4.0mm and 9.5mm-13.5mm hot plate coil of most steel mills is basically equivalent, and the price of hot plate coil of 3.1-4.0mm and 9.5mm-13.5mm may be higher than that of 4.0mm-9.5mm plate, and the representative specification of hot plate coil is 5.5mm thick, Under normal circumstances, the price of flat plate is slightly higher than that of rolling plate.

9. Cold rolled coil

Generally, the thickness of cold-rolled coil (in the form of plate or coil) is between 0.2mm-3.0mm, in which the price of 0.2mm-1mm (excluding 1.0mm) gradually decreases from thin to thick. The price of products with 1.0mm-2.0mm is basically the same. The price of cold-rolled coil larger than 2.0mm but less than or equal to 3.0mm is slightly higher than that of 1.0mm-2.0mm group spacing, and the representative specification of cold-rolled coil is 1.0mm, Under normal circumstances, the price of flat plate is slightly higher than that of rolling plate.

10. Galvanized steel sheet and coil

Galvanized steel sheet is to prevent the surface of the steel plate from corrosion and prolong its service life. A layer of metal zinc is coated on the surface of the steel plate, which is called galvanized steel sheet. According to the production and processing methods, it can be divided into the following categories:

① Hot dip galvanized steel sheet: the thin steel sheet immersed in the molten zinc bath to make its surface adhere to a layer of zinc. At present, the continuous galvanizing process is mainly used, that is, the rolled steel plate is continuously immersed in the melting zinc bath to make galvanized steel plate;

② Alloyed galvanized steel sheet: this kind of steel plate is also made by hot-dip method, but it is heated to about 500 ℃ immediately after it is out of the tank to form alloy coating of zinc and iron;

③ Electroplated galvanized steel sheet: the galvanized steel sheet produced by electroplating method has good processability. However, the coating is thin and its corrosion resistance is not as good as that of hot dip galvanized sheet;

④ Single side plating and double side difference galvanized steel plate: single side galvanized steel plate, that is, only one side galvanized products. It has better adaptability than double-sided galvanized sheet in welding, coating, antirust treatment and processing. In order to overcome the disadvantage of single side without zinc coating, there is another kind of galvanized sheet coated with thin layer of zinc on the other side;

⑤ Alloy, composite galvanized steel plate: it is made of zinc and other metals such as lead, zinc alloy and even composite plating. This kind of steel plate not only has excellent antirust performance, but also has good coating performance. In addition to the above five, there are color galvanized steel sheet, printing and coating galvanized steel sheet, PVC laminated galvanized steel sheet, etc. However, hot-dip galvanized sheet is still the most commonly used one at present. According to the use, galvanized steel sheet can be divided into general use, roof use, building outside plate use, structural use, tile ridge plate, drawing and deep drawing.

Galvanized sheet: the general specification is 0.3 mm-2.0 mm, and its price gradually decreases from thin to thick. The representative specification of galvanized sheet coil is 1.0 mm.

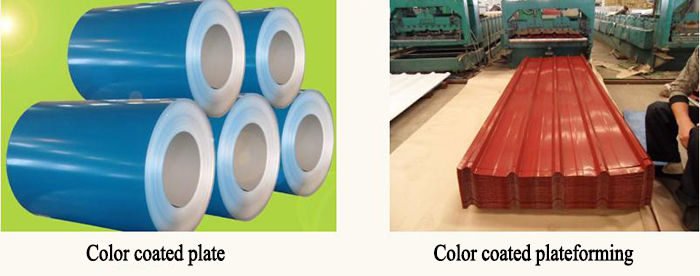

11. Color coated plate

Generally, the color coated substrate has hot-dip galvanizing and aluminizing zinc plating. It is sprayed on the hot-dip galvanized sheet and aluminized zinc plate. After several times of spraying and baking, the color coated plate is produced. The substrate of color coated sheet can be divided into cold-rolled substrate, hot-dip galvanized substrate and electro galvanized substrate. The coating types of color coated board can be divided into polyester, silicon modified polyester, polyvinylidene fluoride (PVDF) and plastisol. The color of color coated board can be divided into many kinds according to the user's requirements, such as orange, cream yellow, deep sky blue, sea blue, scarlet, brick red, ivory, porcelain blue, etc. The surface state of color coated board can be divided into coating board, embossing board and printing board. The market use of color coated board is mainly divided into three parts: construction, household appliances and transportation. Among them, the construction industry accounts for the largest proportion, followed by the household appliances industry, and the transportation industry only accounts for a small part. Generally, hot-dip galvanized steel sheet and hot-dip aluminum zinc steel plate are used as base plates for building roof, wall and door of industrial and commercial buildings such as steel structure workshop, airport, warehouse, freezer after being processed into corrugated board or composite sandwich panel with polyurethane. The color plate of household electrical appliances is generally based on galvanized steel and cold plate, which is used to produce refrigerators, large air conditioning systems, freezers, bakers, furniture, etc. In the transportation industry, zinc plating and cold plate are commonly used as base plates, mainly used for oil pan, automobile interior parts, etc.

Color coated plate: the general specification is 0.25 mm-0.7 mm, and its price gradually decreases from thin to thick, and the representative specification of color coated plate is 0.47 mm.