Construction scheme of steel structure warehouse

- 05 Jul 2019

- steel structure

1. Pre-installation preparation

1.1 Machinery and material preparation

1.1.1 Main machines: hand drill, cutting machine, riveting gun, drill, hammer, etc.

1.1.2 Lofting tools: plunger, ink bucket, horizontal ruler, water pipe, steel tape ruler, rope.

1.1.3 Installation tools: screwdriver, hammer, wallpaper knife, movable handle, pliers.

1.1.4 Installation materials: self-tapping nails, expansion bolts, cement nails, bolts, rivets, welding rods, screws.

1.1.5 Auxiliary materials: glass glue, rubber gun.

1.1.6 Matching tools: mobile scaffolding, crane.

1.2 Material transportation

1.2.1 Check the road condition and choose the best transportation route.

1.2.2 All materials should be transported to the site for installation.

1.2.3 Different transport methods should be chosen for different components.

1.2.4 Components should be handled lightly and placed lightly. They should not be picked up, thrown or wrestled sequentially.

1.2.5 Careful loading, reasonable and reliable binding, keep clean, prevent vehicle vibration damage items.

1.2.6 In transportation, storage and construction of components, measures should be taken to prevent damage, deformation and loss.

1.3 Nursing, counting, repairing

1.3.1 Specialized personnel should be set up to guard against material loss after entering the field.

1.3.2 Before installation, the components should be checked carefully according to the detailed list of the components in the board room, and the missing components should be registered in time for weighing, specification and quantity; the deformed and paint-removed components should be repaired in time; and the dirt, mud and dust on the surface of the objects should be cleaned up in time.

1.4 Square Pipe Installation/p>

Strengthen square pipes on site according to the drawings of steel structure warehouse provided by Party A. All square pipes are fixed with self-tapping screw.

2. Installation of Color Plate in Steel Structure Storehouse

2.1 Installation of External Wallboard

Install the external wall panels according to the layout. Make sure the wall panels are clean before installation.

External wall panels should be installed from left to right.

The joints of exterior wall panels should be directed against the wind.

2.2 Window fittings installation

Installation sequence: top and bottom receptacles of window sill —→ window frame installation —→ window fan installation —→ window lock hook —→ gluing

Adjust the window frame to make it horizontal, vertical, high and low and flat, adjust the support between columns to make the window frame and the column joint inside and outside uniform.

Glue the seams between the window sill receptacles and the wall panels, the window frames and the columns and the window frames. The windowsill receptacle and wallboard behind the house should be glued, and the protective film should be torn off before gluing. The ends of the windowsill closure shall be sealed with glue.

Install window sash

Install window lock hook. According to the position of the lock hook on the window fan, installing the lock hook on the window cabinet should ensure that the position of the two lock hooks is identical, the installation is firm and the switch is flexible.

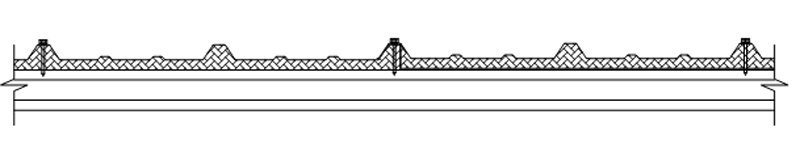

2.3 Roof installation

2.3.1 Construction sequence of steel roof slab: roof, edge receptacles, gluing

2.3.2 Roof tiles and purlins are connected with tapping screws. The row nails are shown below.

Each corrugated roof has a nail, and each tile has a nail in the roof and the middle, at the joint of the tile.

2.3.3 The roof tiles and roof tiles are connected by rivets 4*20. At the intersection of roof tiles and roof corrugates, models should be made and cut with iron shears after marking. As shown in the figure, the cutting size should be matched with the size of the roof corrugates to avoid being too large or too small. Attention should be paid to ensuring that the center of the ridge tile coincides with the vertical center of the roof. After cutting, a rivet should be punched every other corrugation.

Seal the joints and rivets with glass glue.

2.3.4 Rivets are used to connect the side closure of gables with roof tiles and gables. The rivet spacing is 400 mm. The side closure of gables should be lapped along the direction of water flow.

Sealant seals shall be applied to the side-closing joints of gables and rivets.

2.3.5 The seams and rivets of the roof components are pulled and sealed with glass glue for tapping the nails. It is strictly forbidden for people to walk on them.

3. Quality requirement

3.1 Quality Requirements for Installation of Steel Structure Components

3.1.1 The surface of steel components is clean and free from oil, mud, sand and dust.

3.1.2 The coating damaged during transportation, storage and installation should be repaired.

3.1.3 The installation allowable deviation shall meet the internal quality inspection standards of the company.

3.2 Quality Requirements for Installation of Wallboard and Roof Panel

3.2.1 Roof tiles and wall panels should be flat and clean, the joints should be straight, the vertical and horizontal overlap joints should be straight, the cornices and the lower end of the wall should be straight, without error drilling, the joints should be even and tightly without warping.

3.2.2 Gables side plate and ridge tiles should be straight, fixed and reliable and no loosening.

3.2.3 The installation allowable deviation shall meet the internal quality inspection standards of the company.

b3.3 Allowable deviation of door and window installation

3.3.1 Installation of door and window frames should be horizontal and vertical, with the same height and plane.

3.3.2 The connection between frame and column should be firm, without shaking, and the gap should be even.

4. Acceptance of work

<4.1 After the installation of the steel structure warehouse is completed, the construction team should do a comprehensive self-inspection. The self-inspection of the team should be a general inspection, and the problems found in the self-inspection should be dealt with in time./p>

4.2 After the team has passed the self-examination, fill in the self-examination record and report it to the supervisor.

4.3 The supervisor shall organize relevant personnel to carry out inspection and acceptance according to the situation of self-inspection. Inspection and acceptance should be the combination of general inspection and sampling inspection. Notify the team to deal with the problems detected in time. After qualified, the supervisor and relevant personnel sign the acceptance certificate of steel structure warehouse, which serves as the basis for the team to settle wages and complete the installation of the board house.

4.4 Small-scale projects are managed by the director (medium-sized projects by the installation manager, large-scale projects by the company's production manager). Users and relevant personnel are invited to carry out the acceptance and acceptance of the work between Party A and Party B. The problems raised by Party A shall be dealt with separately according to the specific circumstances. Hand over acceptance slip after qualified.

4.5 Quality inspection should run through the whole production process. Inspectors at all levels should take the initiative to work ahead, eliminate quality problems in the bud, and try not to "post-mortem autopsy".

4.6 After acceptance, the acceptance results will be recorded in detail (self-inspection records, acceptance slips) and filed for reference.

Staffing table for personnel and mechanical equipment

| Type of work | Staff(Quantity) | Notes |

|---|---|---|

| Welders | 1 | |

| General worker | 8 | |

| Electrician | 1 | |

| Total | 10 |

5. Installation of Portal Scaffolding and Notices

5.1 The span of the portal frame should conform to the current industry standard "Portal Steel Tube Scaffold" (JGJ76), and cooperate with the cross support specifications.

5.2 When removing scaffolding, workers must wear safety hats, seat belts and anti-skid shoes.

5.3 The inner and outer sides of the portal frame shall be provided with cross support and shall be locked with the lock pin on the portal frame pole.

5.4 Technical safety measures:

5.4.1 Unmatched portal frames and accessories shall not be used in the same scaffold.

5.4.2 When erecting, the cross support, horizontal frame or scaffold should be set up in time following the installation of the gantry. the scaffold must be fully laid at the working level.

5.4.3 The lock wall and hook connecting the portal frame and accessories must be locked.

5.4.4 Scaffolding must pass quality inspection and acceptance check after erection, and it can be put into use only after it is qualified.

5.4.5 The scaffolding erector must be a healthy worker with skilled operation experience. Personnel on duty should undergo regular physical examination, and only those who are qualified can be on duty with a certificate.

5.4.6 Scaffolders must wear safety hats, seat belts and anti-skid shoes.

5.4.7 The quality of scaffolding components and erection shall be checked and accepted in accordance with the provisions of this Code, and the scaffolding shall be used only after it is qualified.

5.4.8 The construction load on the working layer shall conform to the design requirements and shall not be overloaded. It is strictly forbidden to suspend lifting equipment.

5.4.9 Safety inspection and maintenance of scaffolding shall be carried out in accordance with the regulations. Fire prevention measures and special guards shall be provided for electrical and gas welding operations on scaffolding.

5.4.10 The height of portal mobile scaffolding exceeds 3 meters, requiring two groups of portal mobile scaffolding to connect firmly to ensure stability; the height of portal mobile scaffolding exceeds 5 meters, requiring three groups of portal mobile scaffolding to connect firmly to ensure stability.

5.4.11 According to the use characteristics of portal scaffolding in this project, it is used within the scope of indoor shared space. The concrete floor slab of the elevator core shaft wall and railing position increases the tie point and support to increase the stability.

5.5 Installation steps: alignment of spring portal frame pole →placement of base →erection of portal frame from one end and then installation of cross support →installation of horizontal frame (or scaffold)→ installation of horizontal reinforcement pole →according to the above steps, layer by layer upward installation →installation of scissors brace →assembly of top step railings.

5.6 The erection of portal frame must cooperate with construction supervision to ensure the stability of portal frame.

5.7 The installation of horizontal reinforcement rod and scissors brace should meet the structural requirements and be synchronized with the erection of portal frame.

5.8 Horizontal reinforcing pole should be fastened to the inside of the pole with fasteners, and scissors should be fastened to the outside of the pole with fasteners.

5.9 Seal bar must be added to the port of passage.

5.10 The lower part of the working surface platform, the straight climbing ladder and other necessary parts must be hanged to prevent falling net.