Door and skylight design of steel structure workshop

- 26 Sep 2019

- steel structure

1. Door

The gates of single-story industrial steel structure workshop are mainly used for production, transportation and people entrance and exit. Therefore, the size of the gate should be determined according to the type of the transportation, the shape and size of the transported cargo and the traffic height. Generally, the size of the gate is 600-1000 mm wider and 400-600 mm higher than the full-loaded vehicle.

The types of gates and their construction methods of single-storey industrial buildings are basically the same as those of civil buildings. The door frame of the steel structure workshop door has two types: reinforced concrete and brick.

2. Skylight

2.1 Rectangular skylight

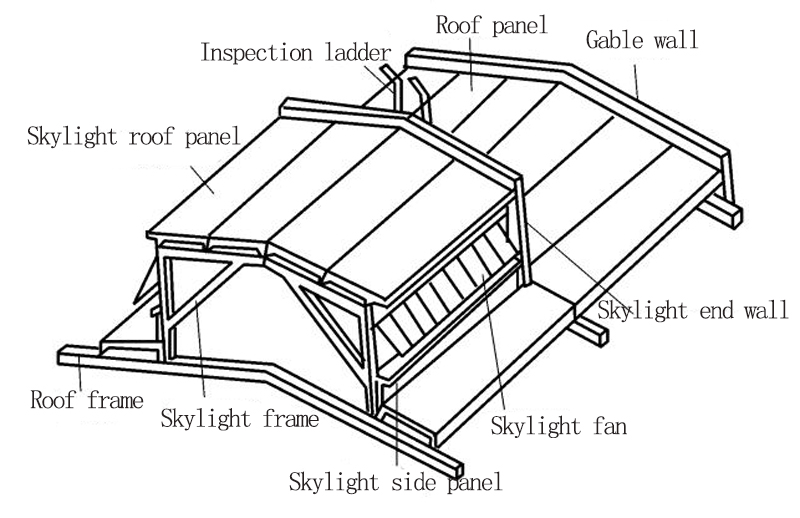

The rectangular skylight is arranged along the longitudinal direction of the workshop. In order to simplify the construction and leave the exit for roof inspection and fire protection, there is usually no skylight between the two ends of the steel structure workshop and the first column of the transverse deformation joint. A fire inspection ladder for the skylight roof shall be provided at the end wall of each skylight. The rectangular skylight is mainly composed of a skylight frame, a skylight roof, a skylight end wall, a skylight side panel and a skylight fan, as shown in the figure:

Composition of rectangular skylight of industrial workshop

2.2 Skylight frame

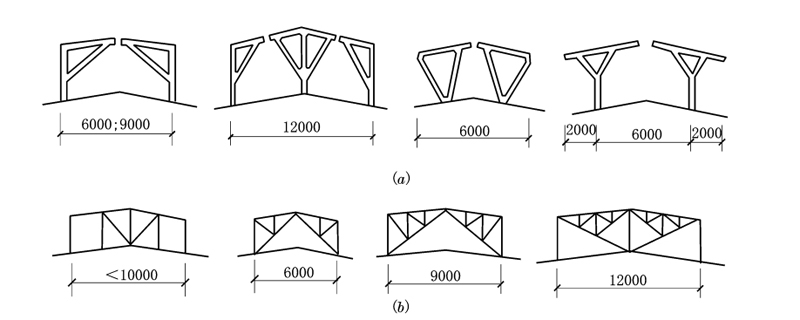

The skylight frame directly bears all the loads of the skylight roof. The skylight frame has two types of reinforced concrete skylight frames and steel skylight frames. The span of the skylight frame is 1/2 to 1/3 of the span of the workshop, and the height is 0.3 to 0.5 times the span of the skylight frame. The form of the commonly used skylight frame is as shown:

Industrial workshop skylight window types

(a)Reinforced concrete combination skylight frame; (b)steel skylight frame

2.3 Skylight fan

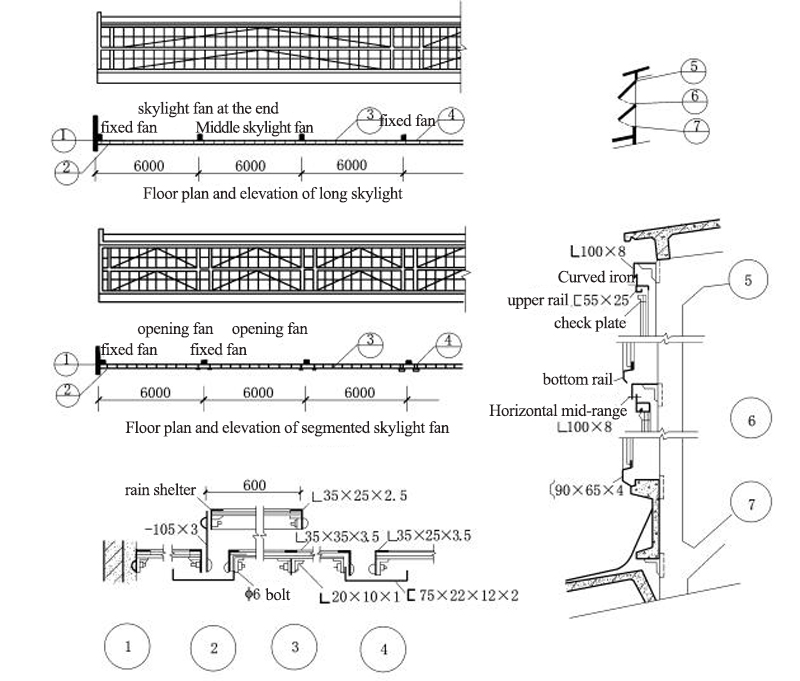

Steel skylight fans are the most widely used in workshop skylights, and other materials such as wood and plastic can also be used. There are two types of opening of the skylight: the upper suspension type and the middle suspension type. For easy opening, the upper hanging window should be used. The upper suspension steel skylight fan is composed of several units such as an opening fans and fixed fans. It can be arranged as a long skylight fan and a segmented skylight fan.

Composition of Suspended steel skylight fan in industrial workshop

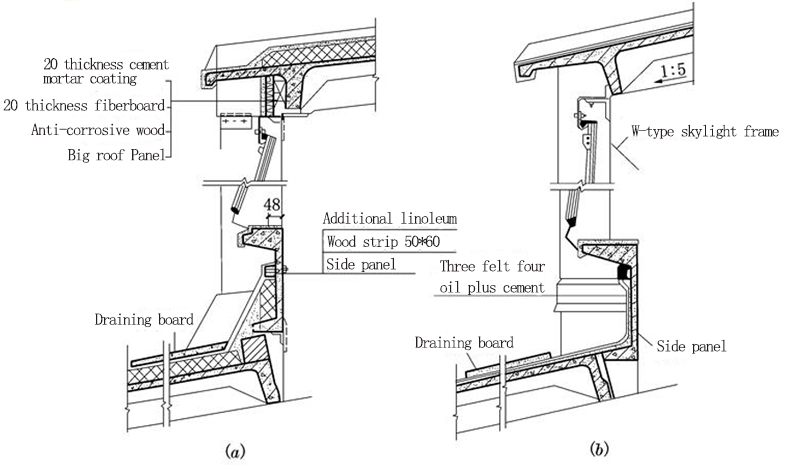

2.4 Skylight side panel To prevent rainwater from splashing into the workshop and to prevent snow from obscuring the skylight fan, a skylight side panel should be placed under the skylight fan. The skylight side panels are mostly made of light-weight panel, such as reinforced concrete trough panels or asbestos cement corrugated, and their structures are as shown:

Skylight cornice and side panel

(a)Twin skylight frame(roof heat-insulation); (b)double V shape skylight frame(no heat-insulation)

2.5 Skylight roof and cornice

The construction of the skylight roof is the same as that of the steel structure workshop roof. Due to the small width and height of the skylight, the cornice of the skylight is mostly made of provocative roof panels, and the length is 300-500mm.

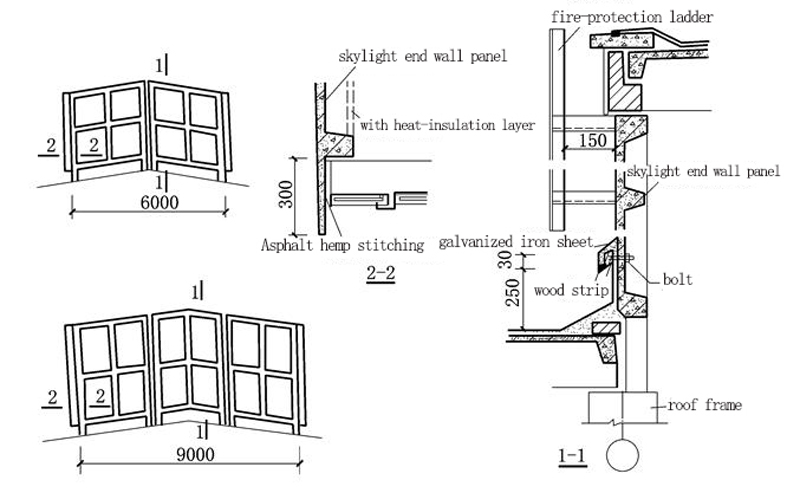

2.6 Skylight end wall

The gable at the two ends of the skylight is called the skylight end wall. Prefabricated reinforced concrete end walls and asbestos tile end walls are commonly used on the skylight end walls. The prefabricated reinforced concrete end wall can be spliced with 2 to 3 plates according to its span, and its structure is as shown:

Reinforced concrete end wall panel of industrial workshop