Manufacturing Process of Steel Structure

- 11 Jun 2019

- steel structure

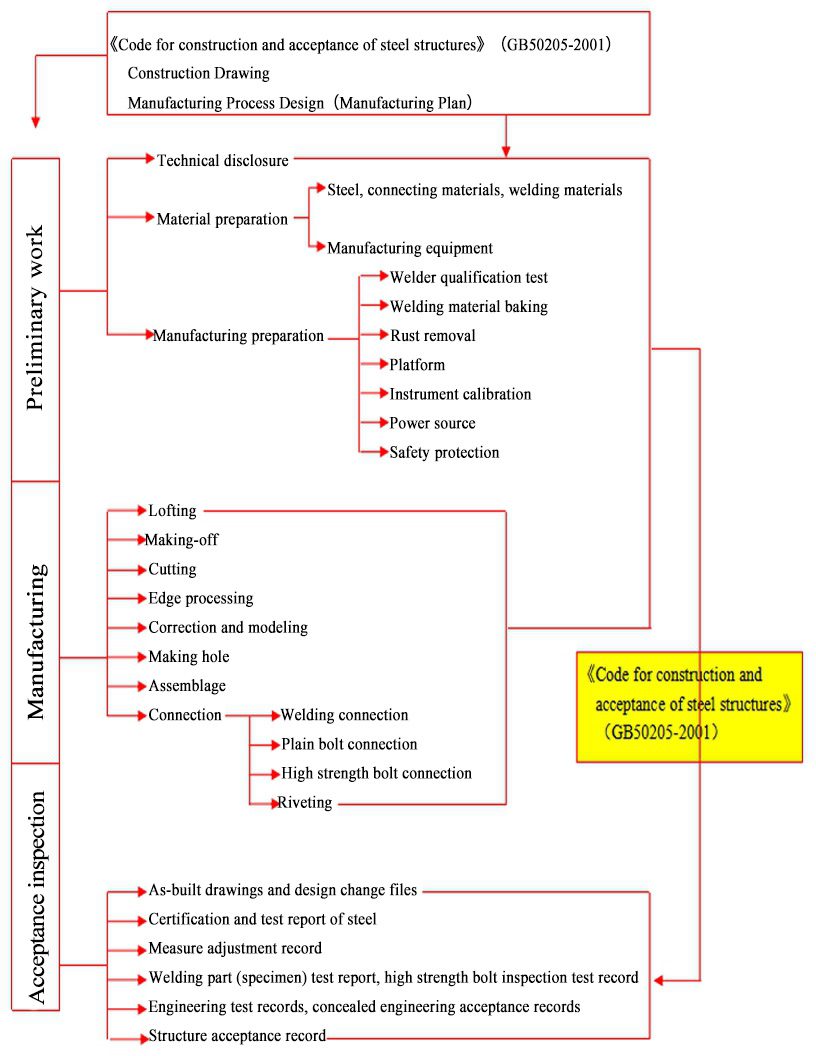

1.Equipment quality control program diagram

2.Steel Components Manufacturing

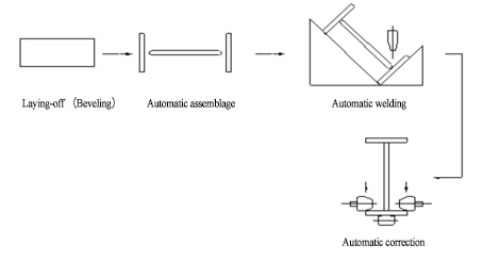

Steel structure manufacturing is mainly divided into two parts: one is H-type steel beam and column processing.

H-type steel beam and column processing:

2.1 Lofting: The professional lofting worker is required to accurately loft on the processing surface and assembly large sample plate during every construction process, such as steel sheet lofting and cutting, H-steel assemblage, assembly of various components and parts, components pre-assembly. After the Lofting, it must be inspected by the inspector to make sure the accurateness of geometrical dimensions of the parts and components, the shape and position difference, the angle, the installation contact surface, etc.

2.2 Scribing and Making-off: For the smaller-sized plates and rods, the manual scribing and making-off are used in the case of unnecessary CNC cutting. The scribing and making-off personnel should be skilled in making prototypes and sample rods, familiar with the symbols and texts marked on the prototypes and sample rods, and figure out the quantity of the materials.

2.3 Laying-off (including beveling): including gas cutting, shearing and beveling. The main equipment for laying-out and cutting of our company include Isa-Hancock plasma, flame multi-head CNC cutting machine, trolley type flame cutting machine, horizontal band sawing machine, beveling machine and shearing machine. Correct the steel plate or profile with a straightening machine before cutting. For welded steel plates or H-beams, inspection and flaw detection must also be carried out.Only when it is qualified,the cutting can be processed. The processing requirements shall be based on the company's internal control standards to inspect the cutting surface, geometrical dimensions, shape tolerances, incision sections, spatters, etc. After the inspection is qualified, Stack them reasonably, make the qualified mark and put the components number.

The main precision requirements for Laying-out the cutting are shown as below:

| Item | Allowable variation |

|---|---|

| Width and Length | ±3.0mm |

| Edge chipping | Not more than 1.0mm |

| Perpendicularity | More than 1.5mm but not more than the 5% of panel thickness |

| Tip tilt value of section steel | Not more than 2.0mm |

| Beveling angle | Not more than ±5 |

2.4 H-type steel assemblage: assemblage mainly refers to the spot welding fixed position before submerged arc welding of H-beam. The assemblage is carried out on the automatic assembly machine. Before assembly, Remove the burrs and slag on the flange plate and the web, and then correct it. The center line and the positioning line has to be drawn by the laying-out personnel. After the inspection is qualified, the assemblage welding fixed position can be allowed to carry out on the assembly machine.

The precision requirements for H-type steel assemblage are shown as below:

| Item | Allowable variation |

|---|---|

| Height | Not more than±2mm |

| Web plate center offset | <2mm |

| Head flush | <3mm |

| Top tight surface clearance | <1.5mm |

2.5 Submerged arc welding: Submerged arc welding mainly refers to the welding of H-beams of steel columns and steel beams. Our submerged arc welding of steel columns and steel beams of this project is: normal H-beam adopts gate submerged arc welding electromechanical welding, While large amount and regular H-beams are produced on the H-beam automatic production lines. During submerged arc welding, the corresponding welding wire, current, voltage and welding speed must be adopted according to the thickness and variety of the steel plate. At the same time, the quality of the flux, especially the dryness of the flux. The H-beam welding should be corrected later.

The basic quality requirements of H-type steel are as follows:

| Item | Allowable height |

|---|---|

| Depth of section | 500,±2mm; 500-1000,±3mm; |

| Web plate center offset | 2mm |

| Verticality of flange plate to web plate | b/100,also not more than 3mm |

| Partial flatness of web plate | t﹤14,not more than 3mm; t≧14,not more than 2mm; |

| Torsion resistance | H/250,and not more than 5mm |

| Welding quality | 2、3 grade |

| Welding height | Same with the web plate thickness |

2.6 Locking and head processing: The column and the main beam are connected by high-strength bolts. After the H-beam processing and inspection is qualified, the end milling is performed, and the size should be accurate during processing.

2.7 Assemblage of components: The assembled components are mainly columns, roof steel beams and supports.The large sample should be laid out before assembly. End-milling of the H-beam end plates of beams and columns shall be carried out before welding. The assembled components are spot-welded and are ready for formal welding after being inspected.

2.8 Manual welding of assembly parts: The manual welding of assembly parts adopts Lincoln CO2 gas welding machine. The company's welding personnel are all certified according to the regulations. All the welding of the company (including submerged arc welding, gas welding, arc welding) must also be marked with the welder's stamp number.After welding,the appearance text and ultrasonic inspection should be carried out by the inspector. Only when it is qualified,then the qualified mark can be laid out.

The processing quality requirements of general components (beam and column assemblage welding quality requirements) are detailed in the following table:

| Item | Allowable variation | |

|---|---|---|

| Height(length) | column | beam |

| Tortuosity sagittal height | ±5mm | ±5mm |

| Tortuosity | Not more than 8mm | Not more than 8mm |

| Section geometric size | ±3mm | ±3mm |

| Flatness of baseboard | 3mm | / |

| Head plate tilt | 2mm | 2mm |

| Flatness of friction surface | 1.5mm | 1.5mm |

| Stiffener plate, positioning Plate displacement | 2mm | 2mm |

2.9 Hole making: The parts of the steel structure are accurately mechanical drilled by a universal rock drill . The components are drilled by a three-dimensional drill or a magnetic drill with a scribe line and a template. In order to ensure the accuracy and quality of the drilling,the reference axis and center of hold should be laid out by loft man during the mold drill. For CNC machining,only when the first processed product was qualified by inspector,can it be drilled in batches. The parts, components must be inspected and qualified after welding by the inspector firstly, then it can be moved to another procedures.

2.10 Correction: The correction work runs through the whole processing of steel structure fabrication, from preparation to laying-off, submerged arc welding, assembly and manual welding, etc., to ensure that the size, quality and shape of the components meet the requirements of the specification. At present, the methods of correction mainly include automatic correction, flame correction, etc. The main equipment adopted is H-beam straightening machine.

2.11 Friction surface treatment: the end of components’ joint friction surfaces should be milled by a milling machine, and the friction surface is treated by a shot blasting machine to treat the surface friction degree, which naturally causes floating rust. At the same time, the test specimen should be made of should be made of the same material and processing method.And it should be tested by the friction coefficient test to ensure that the friction coefficient meets the specified requirements.

2.12 Surface treatment of components: After processing, the parts and components shall be edge-processed according to the regulations to remove burrs, welding slag, welding spatter, dirt, etc.and be inspected on surface. After the products are finished and the surface is removed, the surface derusting treatment is performed by a shot blasting machine. The descaling level should be above Sa2.5.

2.13Paint:After derusting,the components should be cleaned immediately and sprayed with anti-rust primer. The requirements of the paint should be in accordance with the design regulations. The paint process should be carried out according to the operation instructions and the corresponding paint and instruction manual. The ambient temperature and humidity are controlled by a temperature and humidity meter to ensure compliance with the requirements of the corresponding paint process. The thickness of the spray is controlled by the thickness gauge. The thickness of each paint should be controlled according to the instruction manual. After the paint,It should be marked by specified person according to the requirements of the drawings. The main marks and signs of the components are the assembly number, the height reference point, the assembly center line of the reference line, the hanging points and others. The main equipment adopts is high pressure airless paint spraying machine.

2.14 Acceptance: When the number of finished products reaches the requirements of a cross-test assembly, a trial assembly shall be carried out in the factory under the guidance of technical and quality engineers to check the overall quality and installation of the components to ensure smooth installation on site. At the same time, the inspection and test results should be inspected by the full-time inspector. After the above inspections are passed, the certificates shall be affixed to the components for packaging and delivery.

3. Safety work During steel structure manufacturing

The steel structure has high production efficiency, but the working space is moved in a large amount and frequently and the large amount of mechanical equipment are adopted during each processed.All of them need protection. Therefore, the safety measures in the production process are extremely important, especially in the production of large-span steel structures and high-altitude operations. It is necessary to attach great importance to the prevention of safety accidents.

3.1 Operators and production management personnel entering the construction site should be dressed in labor protection articles, and the operation should be based on the regulations.

3.2 Safety learning and safety education are necessary for operators,and the worker with special skill must be certified.

3.3 In order to facilitate the operational activities of manufacturer of the steel structure and the operator, the components should be placed at a certain height. Assembly tire frame, welded tire frame, and various shelves should be 0.4m-1.2m away from the ground.

3.4 The stacking and shelving of components should be very stable, and support or positioning should be provided if necessary. The stack of components must not exceed two layers.

3.5 Rigging and spreaders should be checked regularly and must not exceed the rated load. Normally worn wire ropes should be replaced as specified.

3.6 All the manufacture and installation of various tires in the processing of steel structures shall be calculated for strength and shall not be estimated empirically.

3.7 Oxygen, acetylene, propane, power supply, etc. used in the production process must have safety precautions, and the leakage and grounding situation should be checked regularly.

3.8 Corresponding signs, signals, warnings, etc. should be made to the hazard source at the construction site. Operators must strictly abide by the safety procedures of each post to avoid accidental injury.

3.9 Component lifting should follow the instructions of one certain person. When the component moves, no one are allowed to stay and pass in the moving area.

3.10 The safe passages of all production sites must be unblocked.

4. Manufacturer of steel purlin and wall beam

4.1 Production Process:

Plate rolling → Material inspection and verification → Uncoiling → Material splitting → Rolling → Hole machine→Correction → Inspection→Hot galvanized → Package and enter in storage

4.2 Inspection Content:

4.2.1 Check the steel coil number and calculate the width of the coil according to the design requirements of the drawings;

4.2.2 Check the size of material before splitting to maximize the utilization rate.

4.2.3 For cold-formed steel after straightening, the bending height shall not be greater than 1/1000 of its length, and shall not be greater than 5 mm. The distortion of the section shape of the section shall not exceed 1/100 of the width of the limb;

4.2.4 When making holes, the hole diameter of the ordinary bolt should be 1.0-2.0mm larger than the nominal diameter of the rods. The allowable deviation of the hole should meet the following requirements: hole diameter: 0 - +1.0mm; roundness: 2.0mm; center line verticality: ≤ 2.0mm

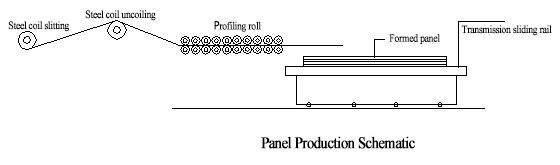

5. In-plant production of lighting panels and accessories

The production of the envelope panel is divided into two parts: one part is 1.5mm thick V840 type lighting roof panel, and the other part is 1.5mm thick V840 type lighting wall panel.

5.1Production Sequence:

According to the classification of components, the sequence is: wall panel → color steel fittings.

After all the components passed the inspections, the certificates shall be affixed to the components for packaging and delivery.

5.2 Production schematic:

5.3 Production process and quality control points:

5.3.1Panel Production:

①Production process principle: Under normal circumstances, the corresponding production equipment is first selected according to the design drawing requirements. and then according to the processing width and transportation conditions, the number of times of connection in the direction of the slope is the least (ie, the production of long boards) is considered for panel layout and Laying-off.

②The main process is:

Raw material enter into storage and inspection → Production process plan determination→Uncoiling and material splitting → Rolling→Inspection→Packaging

5.3.2Inspection content:

①The profiled steel plate after molding shall not have cracks; the paint film shall be free of defects such as cracks and peeling.

②The tolerance length of the formed panel shall not exceed ±7 mm, and the difference in transverse shear force shall not exceed 5 mm.

③The tolerance of the profile size of the formed panel shall not exceed the following limits:

| Depth of section | Allowable tolerance(mm) | Notes | ||

|---|---|---|---|---|

| Coverage width | Pitch of waves | Wave height | ||

| ≤70 | +8 -2 | ±2 | ±1.5 | Coverage: refer to effective coverage width Pitch of wave: Refers to the distance between the center of two adjacent peaks Wave height: refers to effective height of section |

| ≥70 | +5 -2 | ±2 | ±2.0 | |

④The profiled plates shall be stacked separately according to the material and specifications. Heavy objects shall not be stacked on the profiled steel plates, and pollution shall be avoided.

5.4 Production of color steel Fittings:

5.4.1Production process: Material selection → Slitting and cutting → Bending → Inspection → Packaging and enter into storage

5.4.2inspection content:

①Calculate whether the expanded width and the trim width are equal according to the design drawing requirements.

②Check whether the bending angle and size meet the design requirements.

③Check if the surface of the color steel fittings is scratched, and if the surface paint film is scratched or peeled off.

④It should be classified packaged and protected with a film to avoid scratching during transportation.