Safety and civilized measures for steel structure construction

- 15 Jul 2019

- steel structure

In accordance with the requirements of the "Safety Technical Regulations for Construction and Installation Engineering", in the construction of steel structures, we need follow the implementation of the "safety first, prevention-oriented" policy, strictly abide by the "safe production discipline", do a good job in labor hygiene and production safety, improve construction workers production safety awareness and self-protection ability, combined with the regulations of the local labor department, the "Production Safety Management Measures" was formulated to ensure that there were no major accidents throughout the construction period, ensuring the safety of people and property, and creating accident-free projects.

1. Production safety organization management

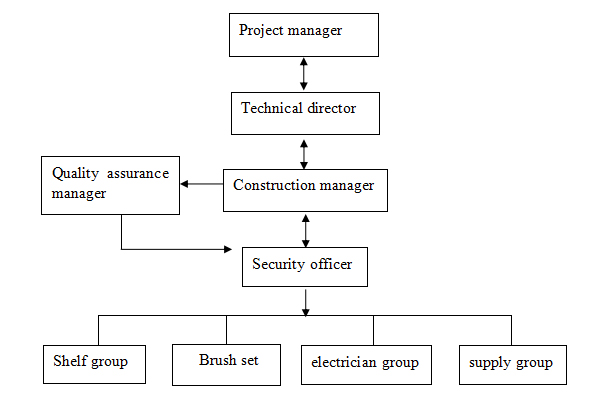

1.1 Starting from the principle of “management of pipe production must be safe”, the project management department establishes a production safety leading group composed of engineering project manager, technical director, construction manager, safety manager and safety inspector. The task is to implement the regulations on production safety. Regulations, research, development of production safety decisions, and overall responsibility for the production safety of the project;

1.2 Under the Steel Structure Production Safety Leading Group, a production safety office consisting of construction manager, safety manager and safety inspector is set up. The task is to do a good job in publicity, training, inspection, supervision and accident handling of production safety;

1.3 Production Safety Assurance Chart

1.4 Qualifications and responsibilities of safety inspectors

A: The safety inspector must select the personnel who have been engaged in the safety management of steel structure production, have been specially trained, have strong sense of responsibility, and can adhere to the principle. The safety inspectors should be relatively stable and should not be replaced at will;

B: The number of safety inspectors is equipped at a ratio of 1:50, and the list is submitted to the local labor department for record;

C: The safety inspector must sign the Safety Production Responsibility with the project manager;

D: The safety inspector must clarify the responsibility system of “seeing, checking and managing”, observe the safety situation on the site, check the use of safety facilities, and be responsible for rectifying and handling hidden dangers;

E: The safety inspector must take the armband to work, complete the handover procedure after the shift, and hand over the site safety record.

1.5 Safety obligations of construction personnel:

A: Construction workers have the obligation to use safety equipment and personal labor safety products;

B: Have the obligation to pay attention to, report and reject accidents and participate in accidents;

C: There is a right to expel people who do not use security tools into the work danger zone;

2. On-site management of steel structure construction safety

2.1 Pre-class safety check

A: Before the work, the “three inspections” will be carried out to check whether the safety devices are firm and defective; whether there are hidden dangers in the second inspection engineering facilities; and whether the mental state and physical condition of the laid-off workers can be adapted to the corresponding operations.

B: The safety inspector must first start and test the safety device and make a demonstration if necessary;

C: For new construction operations, the safety inspector must submit the production safety requirements to the construction personnel.

2.2 Production safety work in the class

A: The safety of the scaffolding, the joints should not be corroded, twisted, broken, and the verticality and horizontal deviation of the poles should be corrected at any time;

B: The safety net should be full under the work area, leaving no holes;

C: When the shelf workers and brush coaters work at height, strictly enforce the safety operation procedures, attach the full body harness and wear a safety helmet;

D: Construction personnel should strictly follow the safety regulations and use labor insurance products, such as wearing safety helmets, gloves, shoes, masks, etc.

E: Spraying construction, attention should be paid to the safety of air compressor ventilation pipes and electrical lines;

F: Check whether the lightning protection device is intact; whether the electrical equipment and the zero connection device are reliable, whether the electric lock box has missing doors and leaks, and whether the cable erection is reasonable;

G: Check the unfinished equipment and scaffolding after the shift, whether there are signs and protective measures;

H: Regularly check whether various machines and equipment, especially dangerous equipment, are kept in a safe state of operation;

I: The paint is stirred, avoiding open flames, and the agitator blades cannot rub the wall of the package.

3. Steel structure engineering construction safety system

A: The company publishes the "Production Safety Code" and has a manual. All departments should establish a production safety responsibility system applicable to the department. The production safety office will conduct inspections at any time. If there is a violation, each member of the safety production leading group has Right to deal with on the spot;

B: Each member of the Safety Production Leading Group has a veto in the production safety work;

C: The construction personnel should follow the instructions of the safety inspector, do not take risky work, and have the right to refuse any violation of the rules;

D: Establish a fire and hot fire approval system at the construction site. Use flammable products must be kept away from open flames, smoking should not be allowed, fires should be in place, people should be separated from fire, and a certain number of portable fire extinguishers must be equipped in the construction site and living quarters;

E: Those who are not allowed to bring alcohol, those with poor mental status, those who are not attentive, and those with certain diseases should be employed. Special types of workers must be certified to work;

F: Safety signs should be set at the construction site, and warning lights should be set in the danger zone;

G: The production safety office should supervise the implementation of the daily production safety system, and provide the construction personnel with labor insurance products (such as safety belts, caps, protective glasses, labor insurance shoes, etc.) to deal with the violation of production safety and labor safety in time. Issues that have not been addressed, report to the project manager in a timely manner, request processing.

4.Instructions on production safety

A: The construction and safety requirements of the owner and the general contractor must be observed in the construction, and the hidden dangers should be rectified immediately;

B: Any accidental accidents caused by the construction party shall be resolved by the construction party. All responsibility shall be borne by the construction party and shall not be related to the owner and the general contractor.

5. Measures for civilized construction

A: Construction workers should advocate "five stresses and four beauty", go to work as "civilized workers", and work as "civilized citizens". No uncivilized and polite behaviors such as fighting, drinking, gambling, etc. are allowed on the construction site. If found, deal with it seriously according to the relevant system;

B: Carry forward the spirit of unity, friendship, and division of labor. If there are difficulties, they should help each other. Skilled workers must do a good job of spreading, helping, and bringing new workers. New workers should learn with humility;

C: After the shift, close the electric gate, pack the tools, and clean the venue;

D: The engineering manager department should try its best to improve the working conditions. The construction site should be ventilated and unblocked. In summer, measures to prevent heatstroke and cool down must be taken.

E: The workplace should be provided with rescue medicines;

F: In order to strictly discipline, strictly demand, and strictly prohibit violations of law and discipline, the Engineering Management Department has formulated the “Code of Construction” and various rules and regulations to regulate the behavior of construction workers.