Steel Structure Modular Container House Building Composition

- 12 Jun 2019

- steel structure

1. Outline

1.1 Steel structure modular container house refers to a container building with a steel material as a frame and a combination of surounding panel and steel frame. All modular components are standardized and designed at the factory, arnd the building components are quickly installed on site by standardized connectors to complete the construction. The design and construction of this modular building project is in line with the principles of generalization, modularity, industrialization and optimized integration.

1.2 The modular container house is a house combined with container building unit module with building use function. The unit module is mainly composed of the top structure, the bottom structure, column, wall, door, window,and the fittings, etc.. And these main parts are installed on site. Since the precision of the components is ensured, the installation in the field can be fast and accurate.

1.3 The design of the container houses is standardized design.The package is flat, which is convenient for transportation, and storage space saving. This kind of house is recyclable disassembled and reassembled freely, energy saving and environmental protection.

1.4 The space layout of the container house is flexible. In addition to the horizontal and vertical connection, it can also be placed on top of each other and set up the floor platform. The Inside partition and wall can be set flexibly in the connected internal space.

2. Application Scope

2.1 It is suitable for the design of container houses with three or less than three floors.

2.2 It is suitable for the design and construction of temporary or mobile housing projects in hotels, camps, tourist attractions, military camps, construction projects departments, booths, villas, shops, etc.

3. Design Key Points

The architectural design of steel structure modular container houses should conform to the principles of module integration, combination diversity and functional practicability. It can effectively utilize space and facilitate construction, and should meet the following requirements according to the use characteristics of the project.

3.1 Reasonable use function and convenient space organization.

3.2 Meet the functional requirements of skylight, lighting, ventilation, sound insulation,heat insulation, waterproof and sanitary.

3.3 Meet the safety requirements of fire prevention, evacuation, protection, etc.

3.4 Meet the requirements of energy saving and environmental protection.

3.5 When the engineering design is selected, the structural calculation can be carried out according to the single container and the connection bearing capacity data provided by the enterprise.

3.6 The architectural design should be coordinated with the structural design. The wall panel opening or the large cantilever arrangement on the body of containers should meet the structural safety requirements.

3.7 Equipment and pipelines should be hung and fixed on the metal part of container house. The internal equipment and pipeline should be pre-design and pre-install with the decoration project, and complete the system installation on site.

3.8 The durability of external pre-installed pipeline shall meet the engineering requirements and be protected against water, corrosion and impact.

3.9 The floor plan, space layout and composition of the container house shall meet the requirements of pipeline installation and maintenance.

3.10 The opening should be pre-positioned if the equipment riser needs to pass through the top and bottom structure of container house. The hole diameter should be considered for installation error and the sealing should meet the requirements of fireproof, waterproof and sound insulation.

3.11 The container house electrical distribution system should use the combined steel structure for the total equipotential bonding. The external interface of the small container house should be equipped with a dedicated socket and should meet the rated current specified by the socket.

3.12 The grounding system such as working grounding, PEN repeated grounding, lightning protection grounding and weak electrical equipment grounding should adopt “common grounding system”, and should adopt its own steel components and foundation steel bars as joint natural grounding body. The grounding resistance should not exceed 1Ω. Equipment with special grounding requirements can be equipped with a separate manual grounding body.

3.13 During the construction of container houses, the principles of environmental protection and energy conservation should be followed in all aspects of materials, design and construction. It is advisable to rationally adopt energy-saving, water-saving, material-saving and land-saving technology measures such as new resources, energy-saving lamps, composite walls and sunshades and then achieve integrated design.

3.14 The structural budget shall be made for various working conditions that may be experienced by the container house after assembling, such as lifting, transportation, stacking, etc., and measures shall be taken for the relative deformation that may occur of various components.

4. The content and introduction of container house

4.1 The basic module of steel structure container modularized house is single module, and we also can provide the stairs, rest room, shower cubicle functional module to satify basic functional needs of the building;A variety of spatial combinations are formed by splicing combinations of different ways of the energy modules.

4.2 Common basic modules are divided into two specifications:6030 type、6024 type

| Item | Type | ||

|---|---|---|---|

| 6030 type | 6024 type | ||

| Outside dimensions(mm) | Length | 6055 | 6055 |

| Width | 3000 | 2435 | |

| Height | 2896 | 2896 | |

4.3 Steel structure modular container house is mainly composed of the following accessories:

Container roof: It is composed of top beam, top corner piece, capping steel plate, heat preservation material, top C type purlin, ceiling plate and wire box.

Container bottom: It consists of bottom beam, bottom corner piece, sealing color board, heat preservation material, bottom C-type purlin, load-bearing floor, decorative floor, drainage trough and other components.

Column: It consists of corner posts, L angles, column middleware, insulation materials and other components.

Outer wall: There are two options, one is the metal surface insulation sandwich panel, the standard wall panel thickness is 75mm, 100mm optional; the other is the thermal insulation wall made of lightweight strip and insulation material, using 50mm and 75mm two Board combination. The main section structure and thermal performance of the external wall are shown in Table 1.

Inner partition wall: There are two options, one is the metal surface insulation sandwich panel, the standard wall panel thickness is 75mm, 100mm optional; the other is the wall with a combination of lightweight strips.

Door: Optional steel doors, broken aluminum alloy doors, plastic steel doors, aluminum-magnesium alloy doors, wooden doors, as required, see Table 2.

Window: Optional plastic steel window, broken aluminum alloy window, see Table 2.

Roof: There is a metal surface insulation sandwich panel slope roof and tile roof.

Supporting accessories include: Outdoor stairs, walkways, guardrails, canopies and other components.

Other spare parts include: Electrical accessories, decorative lines, assembly box accessories, LCL accessories, etc.

Table 1 Main section structure and thermal performance table of outer wall

| Name of wall | Schematic diagram of basic construction | Performance parameter | Wall material and thickness(mm) | Wall thickness(mm)) | Main section thermal resistance R[(㎡·K)/W] | Main section heat transfer coefficient K[W/(㎡·K)] | |

|---|---|---|---|---|---|---|---|

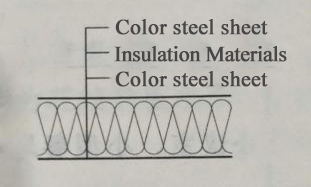

| Metal surface insulation sandwich panel exterior wall |  |

1.Thickness of steel sheet :0.35mm-0.5mm 2.Density of glasswoool 60kg/m³, fire-proof grade A grade; 3.Density of rockwool 120kg/m³, fire-proof grade A grade. |

Glasswool | 75 | 75 | 1.54 | 0.59 |

| 100 | 100 | 2.02 | 0.46 | ||||

| Rockwool | 75 | 75 | 1.67 | 0.55 | |||

| 100 | 100 | 2.55 | 0.37 | ||||

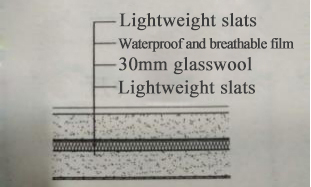

| Lightweight slats Combined outer wall |  |

1.Lightweight slats 50/75mmthickness,areal density≤80kg/㎡,Sound absorption coefficient0.2,fire-proof grade A grade; 2.30mm, density of glasswoool 60kg/m³. |

Lightweight slats | 50+30+50 | 130 | 1.8 | 0.51 |

| 50+30+75 | 135 | 2.11 | 0.44 | ||||

| 75+30+75 | 180 | 2.42 | 0.39 | ||||

Table 2 Door and window matching table

| Name | Type | Description |

|---|---|---|

| Door | Steel door series | Steel door leaf, standard single fan (optional double fan) |

| Broken bridge aluminum door series | 60 series door frame, 5+12A+5 insulating glass | |

| Plastic steel door series | 60 series door frame, 5+9A+5 insulating glass | |

| Aluminum-magnesium alloy door series | Optional glass, metal panel door | |

| Wooden door series | Optional solid wood, solid wood composite door panels | |

| Window | Plastic steel window series | 60 series window frame, 5+9A+5 insulating glass, standard screen window, anti-theft bar |

| Broken bridge aluminum window series | 60 series window frame, 5+12A+5 insulating glass, standard screen window, anti-theft bar |