Steel structure prefab house

- 24 Mar 2020

- steel structure prefab house

We have introduced the container house in details in the previous article, Now we will introduce the color steel prefab house. Through the introduction of the two articles, you can better understand the differences between the container house and the prefab house. I hope it can help you when you purchase this product.

The color steel prefab house is assembled on site, with low cost, high flexibility, and less limited by modulus.

Color steel prefab house

1. Material introduction

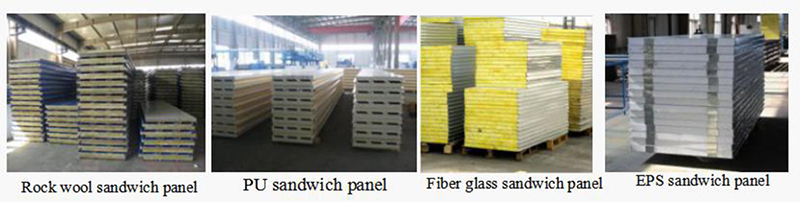

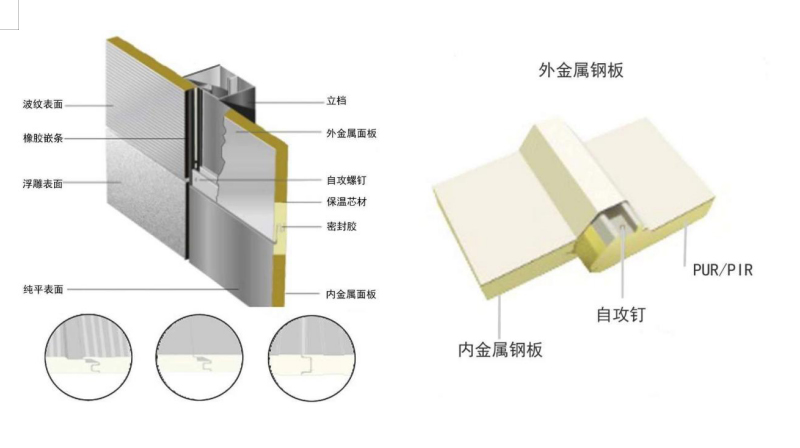

External wall insulation mainly includes EPS insulation sandwich panels (high waterproof strength and low price), glasswool insulation sandwich panels (fire-resistant A1 level, low carbon and environmental protection), polyurethane sandwich panels (high bulk density, good thermal insulation performance) rockwool sandwich panel (fireproof A1 grade, high bulk density, good thermal insulation), etc.

2. Material advantages and disadvantages

2.1 Advantages: The material is lightweight, and the standard modular series is used for space combination, and the construction speed is fast. The structure is safe, anti-corrosion and waterproof. For wet environment, you can use a full set of galvanized to raise the floor. The sandwich panel has its own thermal insulation layer, which has good thermal insulation performance. The service life is about 10 to 15 years. It can be disassembled and reused many times.

2.2 Disadvantages: Fixed modulus, limited span, large span needs to be combined with supporting structure system. It is not suitable to build in areas with high wind.

3. Material properties

3.1 Thermal insulation material: Polyurethane sandwich panel thermal insulation material is polyisocyanurate, which has the characteristics of high heat resistance and high anti flaming.

Rock wool or glass wool sandwich panels are made of high-density rock wool or glass wool.

3.2 Core material density: glasswool 40-60kg / m³; rockwool 80-100kg / m³; EPS 10-16kg / m³; polyurethane 40-60kg / m³

3.3 Structural system: frame-shear wall structure, cold-formed thin-wall light steel structure system;

3.4 Applicability: It can be used at -20 ℃ ~ + 50 ℃. For high humidity environment, it can be equipped with removable galvanized overhead ground.

3.5 Specifications: K-type mobile house span is 5m ~ 18m, length of 1.82m is a standard expansion module (K-type house has low cost and fast installation, and is widely used in various temporary houses); T-type mobile house has a span of 5m and a length of 1.2 m is the standard expansion module (the T-shaped house has no C-shaped steel columns and stiffeners, and the structural parts have good anti-corrosion effects. The roof uses a patented waterproof design without nail holes and no exposed nails, which has a better appearance and overall sealing performance)

4. Construction method

4.1 Foundation practice: The foundation concrete is C20 plain concrete. Firstly, the slab house positioning piles and horizontal piles are released, and the gray line for excavating the foundation trench is placed. Each side of the foundation is placed with a 300mm construction surface, and the trench is cleaned and leveled.

4.2 formwork installation: The formwork uses a wooden formwork, and the formwork is used to place the soil surface of the base trough. Drive the piles at the side of the lower part of the formwork with a distance of 700mm, nail the piles and the formwork with iron nails, drive into the piles at a distance of 200mm outside the formwork, with a distance of 1m, and use diagonal braces between the upper part of the formwork and the pile clinch. The cross section of the template is fastened with a knife, calibrated and reinforced.

There is a 250mm × 400mm deep drainage ditch around the board house, and the slope at the bottom of the ditch is 3%. 120㎜ standard brick, M10 cement mortar masonry, 1: 3 cement mortar stucco, C20 steel prefabricated cover plate.

Note: The foundation can be a strip concrete foundation or a raft foundation. For the construction of temporary houses, a flat concrete floor can be used instead of foundation.

4.3 connection method: bolted.

4.4 Product Construction Node Diagram

4.5 Electromechanical installation: BV plastic copper wires are used to pass PVC flame-retardant pipes (cable troughs) indoors along the ceiling and the wall, and sleeves are used to pass through the walls. The junction box is provided with a junction box, and the lamp mouth is a magnetic screw seat lamp mouth. The power lines in the dormitory are laid separately. The lighting uses 36V low-voltage lamps. The power of the lamps is not greater than 60W. The height of the lamps from the ground is 2.4m.

5. Decoration Practice

5.1 Waterproof and ground practice: The first layer of cement mortar is used to polish the ground, and floor leather or floor tiles or wooden floors are laid. The second floor is thickened with wooden feet. The upper floor leather, kitchen, toilets and bathrooms are set up on a single floor. waterproof.

5.2 Roofing practice: natural drainage of double-colored steel plates

5.3 Interior decoration practices: color steel plate + gypsum board, bamboo wood fiber board, etc.

6. Installation steps

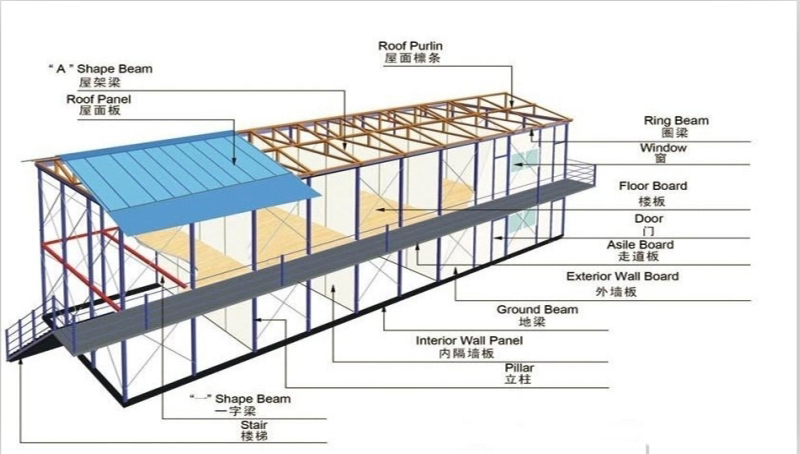

Put the line-installation of ground beams-installation of pillars-installation of floor beams-installation of external wall panels-installation of windows-installation of doors-installation of canopy systems-installation of roof systems-interior partition Board mounting.

7. Installation speed

K-type prefab house: 4 workers can assemble 200 square meters per day.

T-type prefab house: 4 workers can assemble 50 square meters per day.

8. material case