Steel Structure Roof and Wall Panel Installation Guidance-Two

- 22 Jul 2019

- steel structure

The previous article has introduced the pre-installation preparation, layout design and material stacking requirements of steel structure roof and wall panels. Now we will introduce you to the specific installation requirements and methods for steel structure building maintenance systems.

1. Installation Requirements for Panels

1.1 Installation process arrangement: The installation of the profiled metal sheet maintenance system shall be located on a reasonable location of the overall construction process. It is required that all main and sub-structures should be installed, corrected for vertical, tightened bolts, and accepted by the intermediate structure before placing the panel. In the construction of roof works, if there is higher roof nearby needs to be constructed, it should be finished firstly, then the lower part, which will protect the roof project or the supporting surface not for the scaffolding from being damaged.The wall panel project should be started under the condition that the masonry and renovation works under it are completed.

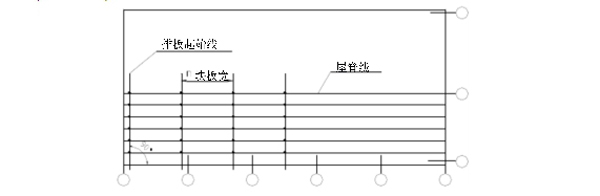

1.2 Installation process: the starting point of the row panel is marked on each purlin (wall beam) along the span direction. The connecting line of each point should be perpendicular to the longitudinal axis of the building. And then continue to label once on the panel width direction every few panels to limit and check the panel installation deviation accumulation.

1.3 After the installation of the roof and wall panel,the secondary paying off should be carry out for the installation of the fittings to ensure the horizontal straightness and verticality of the cornice line, the ridge line, the window doorway, the corner line,etc. If ignoring this step, and using only visual and empirical methods, the installation quality shall never reach the requirements.

2. Panel Lifting

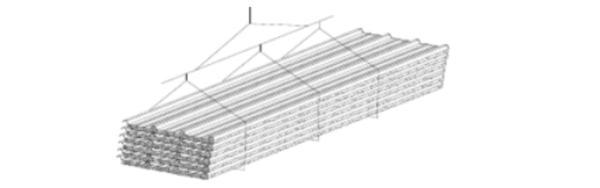

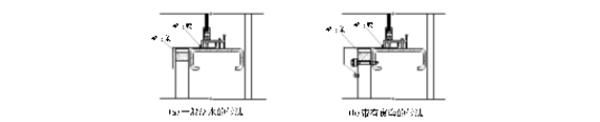

There are many methods for hoisting color steel plate and sandwich panels, such as car lifting, hoisting machinery lifting and manual lifting.

2.1 The car lifting method adopts the iron slings multi-point lifting as shown in the figures, which can lift many pieces at one time. But usually in large-area projects, the raised plates are not easy to send to the installation point, which will increase the long-distance manual handling of the roof. It is not only difficult to walk on the roof,but also easy to damage the installed color plate. In this way, it can not exert the large tonnage lifting capacity advantages of large lifting cranes,the utilization rate is low but the mechanical cost is high. However, the lifting is convenient and the plate to be lifted is not easily damaged.

2.2 The hoisting machine method of lifting allows the equipment to be flexibly moved to the place where it needs to be installed, which is convenient and low cost and short distance in the roof transportation, but the number of lifting is small.

2.3 The manual lifting method is often used in projects where the plate is not long. This method is the most convenient and low-cost, but it must be done with caution. Otherwise, it will easily damage the plate, and at the same time, the manpower and labor intensity is relative high.

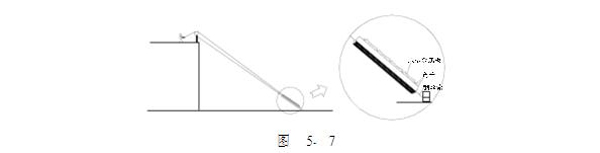

2.4 It is more difficult to use the above methods when lifting the special long panel. The best method is to use the steel wire sliding method (Fig. 5-7), that is, setting a plurality of steel wires at the gable wall of building,casing it, placing plate on the sleeve. The worker on the roof pulls the sleeve along the wire with the rope, and after the special long plate is lifted to the roof and then manually transported to the installation site.

3. Plates Installation

3.1 Steel Structure Roof Plate Installation

3.1.1 Installation sequence and flow direction

①As for single-story roof plate, it usually start from either end of the building. But because of the unique directionality of the different plates, which must be followed. And the lap joints should be placed on the leeward side of the ribs;

②For single-slope double-story roof plate,It should also follow the installation sequence and flow direction of the first strip,Installing the internal layer plate and then the external layer plate.

③For double-slope single-storey roof plate, it is better that the roof panel on both sides of the ridge start from either end of the building at the same time, and follow the principle of laying directionality of the plate and the lap joints on the leeward side of the rib;

④For the double-slope double-storey roof slab, It should also follow the installation sequence and flow direction of the third strip,Installing the internal layer plate and then the external layer plate.

3.1.2 Installation process and installation method

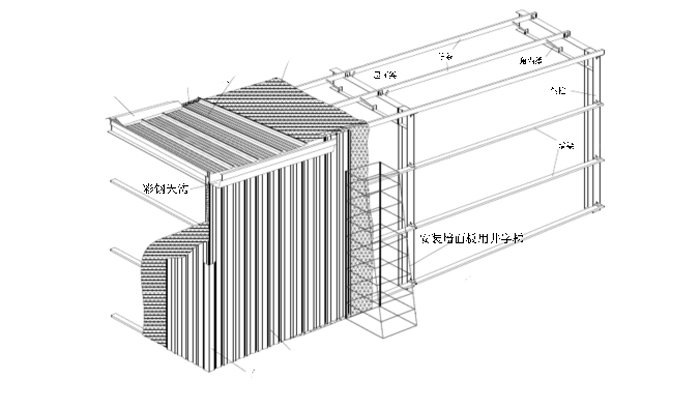

Because the various steel structural type of steel structure roof pane, the installation process and installation method are also different. For the most complicated double-layer board and thermal insulation layer, the installation process is mainly: laying and fixing the inner layer board, laying and fixing of the thermal insulation layer and the laying and fixing of the upper layer. The installation method for each installation process is:

①Laying and fixing of the internal layer plate. The internal layer plate will be divided into above the surface of purlin and below the surface of purlin. As for the installation method of above the surface of purlin, it is similar with the installation of upper layer roof panel. As for the installation method of below the surface of purlin, the mounting platform should be set below it for installation. In order to ensure that the roof purlin is not twisted or bent, and the inner layer of the roof is installed flat and straight, it is not suitable to install the inner panel by hanging the basket on the purlin.

②Laying and fixing the thermal insulation layer. The thermal insulation cotton is usually a fixed-width coil cylinder. Therefore, it can be rolled from one end to the other at the time of laying, and the end is fixed with double-sided taper. As for its longitudinal and lateral directions joint, It should use double-sided tape firstly, then staple, and then lay the upper layer roof panel.

③Laying and fixing the upper layer plate. It will be laid and fixed directly by the installer on the roof purlin. Attention shall be paid to the safety belt and other corresponding safety measures. In the installation of roofing single-layer plate and insulation cotton, in order to ensure the smooth and straight installation of the insulation cotton, the steel wire mesh should be stretched on the purlin before laying the insulation cotton. The installation method is similar to that stretching the flower line when making the quilt core. That is, one person is set at each end of the building, and then the third person transfers the end to the two people along the roof beam along with the wire ring, and finally fixed at both ends of the building.

3.1.3 Fixed Installation

①After the roof panel is laid according to the starting line of the row plate, fastening the two ends with fasteners, and then installing the second panel;

②When it was installed to the next laying off marking point, reviewing the panel installation deviation, and fully tightening the panel when it met the design requirements. If it couldn’t met the requirements, the adjustment shall be made within the next marking section.If it can be adjusted within this marking section, please adjust it and then fully tighten.

③When installing the sandwich panel, the gap between the panels should be squeezed. If the position is accurate but there is still a gap,then filling it with the insulation material.

④After the installation, the roof should be inspected in time for any missing fastening points. For the insulation roof, the gap of the roof ridge should be filled with insulation material;

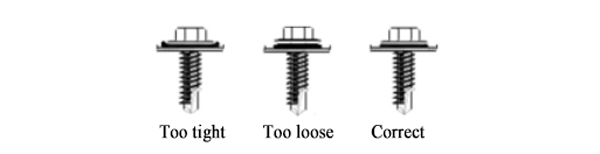

⑤When tightening the self-tapping screws, the degree of tightening should be mastered. Do not over-expose, which will make the sealing gasket turn upside down, and even press down the surface of the panel to accumulate water. Insufficient tightening will cause the in-enough seal and leak. The current method of visually checking the tightening is to see if the rubber around the pad is slightly extruded.

3.2 Wall Panel Installation

3.2.1 Wall panel installation sequence

The installation sequence of the steel structure wall panel is similar to the installation of the roof panel, and also according to the principle of the internal layer firstly and then external layer, and also follow the principle of laying directionality of the plate and the lap joints on the leeward side of the rib. It is usually installed in order from one end to the other end of the building.

3.2.2 Installation process and installation method

The installation process of wall panel also include: laying and fixing the inner layer board, laying and fixing of the thermal insulation layer and the laying and fixing of the upper layer. The installation method for each installation process is:The installation method is to set up a ladder, After the upper end is temporarily fixed with the building cornice, install the panel one by one. The installation of the thermal insulation cotton is the same as the installation of the roof insulation cotton.

3.2.3 Fixed Installation

①After the wall panel is laid according to the starting line of the row plate, fastening the top ends and then the bottom ends with fasteners, and then installing the second panel;

②When it was installed to the next laying off marking point, reviewing the panel installation deviation, and fully tightening the panel when it met the design requirements. If it couldn’t met the requirements, the adjustment shall be made within the next marking section.If it can be adjusted within this marking section, please adjust it and then fully tighten.

③When installing the sandwich panel, the gap between the panels should be squeezed. If the position is accurate but there is still a gap,then filling it with the insulation material.

④When tightening the self-tapping screws, the degree of tightening should be mastered. Do not over-expose, which will make the sealing gasket turn upside down, and even press down the surface of the panel to accumulate water. Insufficient tightening will cause the in-enough seal and leak. The current method of visually checking the tightening is to see if the rubber around the pad is slightly extruded.

3.3 Profiled metal plate installation joint

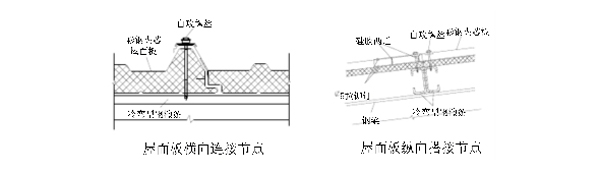

3.3.1 Longitudinal overlap

The longitudinal overlap of single-layer color steel plates should mainly consider improving its waterproof function. The lap length is related to the slope of the roof. When the slope of the roof is greater than or equal to 1/10, the lap length should not be less than 200mm. When the slope is less than 1/10, the lap length should not be less than 250 mm. The length of the wall panel overlap should not be less than 120 mm. The seal at the lap joint should be sealed with double-sided adhesive. It is not advisable to use sealant. The double-sided adhesive should be close to the fastening position.

3.3.2 Horizontal overlap

The transverse overlap of the panels is the overlap between the long sides of the panels. When the lap joint is a hidden lap type, the corresponding lap joint or snap or undercut has been waterproofed. The edge of the plate with the exposed connection has also been waterproofed, so it generally no longer need waterproof.

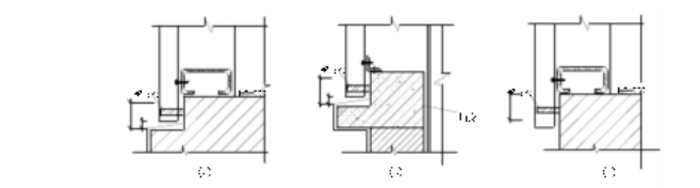

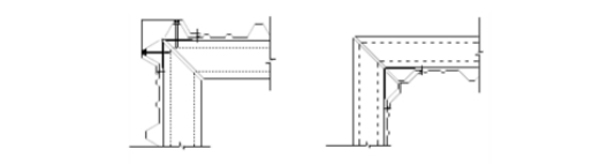

3.3.3 Cornice Structure

The structure of the cornice can be divided into free fall water without seal, free fall water with seal, and external drainage gutter,etc.

①Free Fall water without seal. The appearance is simple, the cornice is picked out from the wall. And the extension length is different according to the plate type, but it should not be less than 300 mm. The serrated gap created between the wall panel and the roof panel shall be sealed by a special plate type water retaining member. When the slope of the roof is less than 1/10, the edge of the trough of the roof panel is bent downward by 5-10 mm as a drip.

②Free Fall water with seal. The length of sealing can be freely selected, it is best to lay the seal plate below the roof plate, and the roof panel extending from the cornice should be not less than 30mm. The sealing plate can be used profiled metal sheet for horizontal or vertical use. And other materials and forms can be used for special requirements.

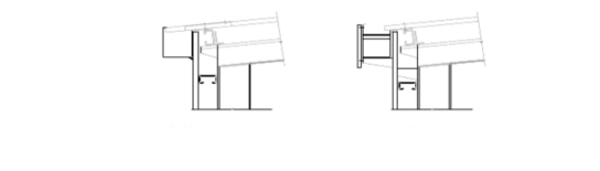

③External drainage gutter cornice: There are two types : with sealing and without sealing as below pictures:

4. High and low span structure

In the case of high and low spans in the color steel plate steel structure, the flooding pieces is used between the high and low spans, and the structural requirements of the low span are similar to those of the ridge construction. The height of the flood at the high span should be greater than 300 mm.

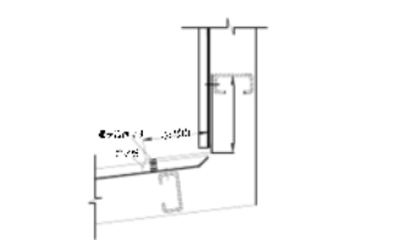

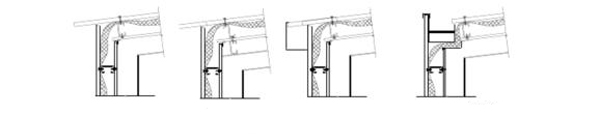

5. Exterior wall Bottom structure

At the bottom of the external wall of the steel plate, an assembled structural joint is formed at the junction of the floor or the low wall. In order to prevent the rainwater flowing down the wall and seeping into the room, the floor or low wall at the junction should be 60-120mm higher than the bottom end of the color wall as shown. A clearance of more than 20 mm should be allowed between the bottom material of the steel plate and the brick-concrete retaining wall to avoid immersion in the rainwater at the bottom, resulting in a corrosive environment to the root of the slab. The zigzag gap between the bottom of the steel wall and the closed brick-concrete structure should be sealed with a sealing strip.

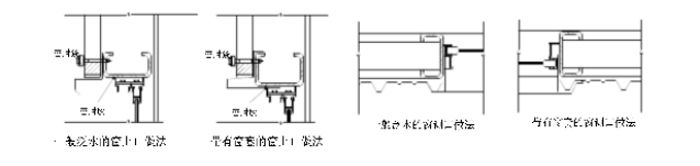

6. Exterior wall door and window opening structure

6.1 The top and side edge of window are as shown in the figure

6.2 The bottom edge of window method

The flooding pieces under the window should be partially turned up at the window edge, and attention should be paid to airtightness and watertight sealing. The intersection of the bottom and the side flooding piece of the window and the wall panel is complicated, and should be treated in detail according to the shape and layout of the panel. Apply a sealant seal around the installed door and window.

7. External Wall Corner Structure

The inside and outside corners of the exterior wall of the color steel plate building shall be packaged with special coverage pieces, and the size of the coverage flooding pieces shall be made according to the actual size after installation.

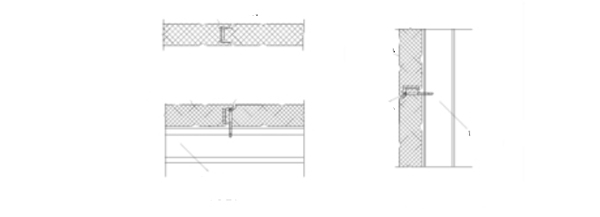

8. The core material among the double layer steel plate

8.1 Roof cornice, free falling water cornice, generally it is the roof panel extending out of the wall panel, and the wall insulation material extends continuously from the roof to the wall insulation layer. The crossing corner of the roof and wall panel should be sealed. Gutter drainage roof cornice. The external drainage method is similar to free falling water. As for the internal drainage, the insulation layer at the bottom of the gutter should be connected with the insulation layer of the roof and the wall, and the decorative color plate should be used to wrap the insulation layer.

8.2 Gable wall cornice. The practice of gable wall cornice is basically same with that of vertical cornice, that is, connecting the wall insulation layer and roof insulation layer to ensure the full coverage of the insulation.

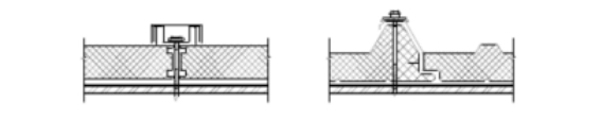

9. Composite sandwich panel installation joint construction

9.1 Connection construction

9.1.1 Sandwich roof panel connection: In the sandwich panel steel structure housing project, the connection is made by aluminum profiles and alloy aluminum rivets or self-tapping screws; for large span roofs, screw connections are used. The corrugated roof sandwich panel is connected exposed, which gas many connection joints. It can be connected at every wave or interval wave with a self-tapping screw. There is a inverted groove plate with a waterproof pad under the hexagonal head of self-tapping screw to enhance the wind resistance of the joint.

9.1.2 Sandwich wall panel connection: The sandwich panel used for wall is mostly flat. In the steel structure combination house, the alloy aluminum profile and rivet is mainly used for connection. As for the building that needs the wall purlin, the vertical wall panel is mostly penetrating connection,while and the horizontal wall panel is mostly the concealed connection.

9.2 Vertical connection

The longitudinal overlap of the sandwich panel is the same as the longitudinal lap joint of the single layer panel. But the overlap length of the bottom layer for sandwich panel and the core material should be removed. Since the width of the supporting purlin of the top and bottom plates of the lap joint is small, it is necessary to set double purlin or add the welding angle steel at the joints.