Steel structure technical measures and safe construction

- 30 Jul 2019

- steel structure

1. Quality Assurance Measures

In the quality management of steel structure construction, quality supervision and process control should be carried out in strict accordance with the relevant national standards and norms, to ensure that each process is controlled, specifically the following measures:

1.1 Establish a comprehensive quality management system, organize various standardized learning, and regularly organize and promote successful experiences.

1.2 Establish a sample guiding route. All professional steel structure construction must be carried out in accordance with the design standards at the beginning.

1.3 Establish a quality inspection team. Each professional construction team shall have quality inspectors. Each process must check the quality of the previous process and be responsible for the next process to ensure that each process is controlled.

1.4 Strengthen technical management, each sub-project must be technically delivered, and take out the construction plan for each process.

1.5 Establish a material inspection system. All materials and auxiliary materials must have complete material reports, specifications, certificates, etc., and must be reviewed and approved for approval, and Party A and the supervisors agree.

1.6 Do a good job in the acceptance of the project and the acceptance record of the concealed project. The concealed project must be reported to the owner and the rational engineer for inspection and confirmation.

1.7 Establish a regular construction system, actively participate in the production scheduling meeting organized by the owners, and we also organize daily scheduling meetings to promptly propose and eliminate quality hazards.

1.8 Establish a reward and punishment system, rewarding fine and bad.

1.9 Establish file of workers of special types of work, and it is strictly forbidden to work without a certificate.

1.10 Prepare professional steel structure construction technical measures, electric welders, painters, etc. must be constructed in accordance with the operating procedures.

2. Process coordination measures

Due to the large number of steel structure construction procedures and frequent cross-operations, the coordination between the various processes is very important to ensure the quality of the project and shorten the construction period. In order to facilitate the smooth progress of the project, the following measures are taken:

2.1 In the construction preparation stage, the person in charge of the site prepares a detailed plan for the connection of each process, comprehensively considers the factors affecting the cross-operation between the various processes, and proposes a solution.

2.2 The site manager shall arrange the operation plans of each construction team in a unified manner. Each construction team shall propose problems that may arise in the cross-operation, and the person in charge of the site shall formulate corresponding solutions for these problems.

2.3 Each sub-item of steel structure engineering shall be constructed according to the principle of bottom-up. Before the next process is not accepted, the construction of the previous process shall not be carried out to reduce rework and speed up the construction progress.

3. On-site civilized construction measures

Civilized construction is an important aspect of showing the image of the construction team and showing the quality of the construction team. The steel structure project is a window for external display and comprehensive planning.

3.1 Basic requirements

3.1.1 Conscientiously implement the “Regulations on the Construction Site Construction of the Construction Project” of the Ministry of Construction.

3.1.2 The steel structure construction site must be provided with obvious signs, and the construction unit is responsible for the protection of the signs. The name of the project, the name of the construction unit, the design unit, the construction unit, the project manager or the person in charge of the project, the date of commencement, the date of completion, and the approval number of the construction permit shall be indicated on the sign.

3.1.3 The construction shall be organized in the approved venue. If it is necessary to temporarily requisition the construction site or temporarily occupy the road, the relevant examination and approval procedures shall be handled in accordance with the law.

3.2 main content

3.2.1 On-site venue management. Temporary facilities and yards shall be set up in accordance with the standard construction floor plan. Materials, components, and mechanical equipment shall not invade the roads and safety protection facilities in the field.

3.2.2 On-site electricity:

A. The installation and use of power lines and power facilities at the construction site must comply with the requirements of safety regulations and safety operating procedures, and be implemented in accordance with the construction organization design rules.

B. The construction site must be equipped with night illumination to ensure construction safety requirements.

Lighting and hand-held lighting fixtures in hazardous wet locations must use voltages that meet safety requirements.

3.3 Construction Machinery

The location of the construction machinery or the route of the construction shall comply with the provisions of the construction plane position map, and shall not arbitrarily encroach on the road inside the yard.

3.4 The site must be clean, tidy and orderly.

3.5 Steel structure construction site Temporary roads are used to harden the ground, and wheel washing equipment is installed at the entrance and exit to prevent the soil on the wheels from being taken out of the field.

3.6 On-site maintenance and maintenance of all curing agents to make the construction site clean and tidy.

4. Environmental protection measures at the construction site

Measures to prevent pollution and soil erosion:

Drainage facilities such as temporary drainage ditch shall be provided on both sides of the building to prevent soil erosion. The wastewater in the construction life should be treated by sedimentation. The waste residue, garbage and spoil should be disposed of properly and piled up at the designated place. It is strictly forbidden to throw away the litter and avoid polluting the environment. After the completion of the construction, in addition to the consent of the owner, all production and living facilities must be dismantled and thoroughly cleaned to restore the original appearance.

5. Construction site maintenance measures

5.1 The distribution of the site is reasonable and orderly. The appearance of the site is neat and civilized. The construction area is strictly separated from the living area. The material areas are piled up neatly and safety protection measures are taken.

5.2 Set a prominent safety warning sign in the construction area and hazardous area.

5.3 The site is to be three-way and one-level, and the drainage is smooth.

5.4 Set the engineering project board, the name and name of the project responsible person, and the safety technical measures signage at the main entrances and exits of the construction site.

6. Project return visit and warranty

After the completion and delivery of the project, according to the contract, within the time limit, the project manager will organize the original project personnel to take the initiative to return to the completed project on a seasonal basis, listen to the user's opinions on the quality of the project, and find effective measures to solve the problem. Solve it in time, leaving no hidden dangers.

7. Safety construction guarantee

7.1 Safety Production Management

Safety production management is an important part of project management, and it is a variety of countermeasures to ensure smooth production and prevent casualties. It manages people and the environment and environment at the production site.

a. Strictly implement the relevant regulations on safety production management.

b. Research adopts various safety technical measures to improve working conditions and eliminate unsafe factors in production.

c. Master the safety situation in production and construction, and take timely measures to rectify and achieve prevention.

d. Carefully analyze the accident seedlings and the cause of the accident, and formulate measures to prevent accidents to prevent the occurrence of repeated accidents.

7.2 Defining safety objectives: Eliminate all safety accidents and fire accidents.

7.3 Establish and improve the safety production responsibility system at all levels and departments, and implement the responsibility to the people, and the parties must sign a safety production agreement.

7.4 New enterprise workers must carry out three levels of education for the company, construction team and team. Strictly check the employees on the job, so that they must pass safety education before they go to work.

7.5 It is necessary to carry out sub-item engineering safety technology disclosure.

7.6 A regular safety inspection system must be established and the inspections recorded.

7.7 Special operations must be certified and must be in compliance with the rules and regulations.

7.8 Establish a file for the handling of industrial accidents, carefully handle the report according to the regulations, and do a good job of “three not letting go”.

7.9 Specific security measures:

7.9.1 Resolutely implement the “Labor Operation Regulations” issued by the Ministry of Labor in accordance with the requirements of the installation process of steel structures. Proper use of personal protective equipment and safety precautions must be worn on the construction site. Slippers or bare feet must be worn. In the case of high-altitude and steep slopes without protective facilities, safety belts must be worn.

7.9.2 Before the installation of the steel structure, all personnel should be given a detailed safety report. The personnel participating in the installation should clearly define the division of labor, use the pre-class meeting, the summary meeting, and the requirements of the site to ensure the safety construction. Cross-over work, to do "three no harm", that is: "do not hurt yourself, not hurt by others, do not hurt others." Safety measures should be taken for operations above 2m from the ground.

7.9.3 High-altitude industries should fasten their seat belts. Ground workers should wear safety helmets. The hand tools of high-altitude workers should not be thrown at high altitude.

7.9.4 The lifting work site should have sufficient lifting passages and maintain a certain safety distance with nearby equipment and buildings. Before the lifting, a low-level test crane should be carried out to verify its safety and stability, and the hoisting rope application The soft material is padded or wrapped to ensure that the components and connecting ropes are not worn. When the components are hoisted, the slings must be tied firmly. The rope buckles must be locked in the hooks. It is strictly forbidden to use the hooks to hook the components. The components are not allowed to be used before they are stable at high altitude.

7.9.5 In the hoisting area of the crane, non-operators are strictly forbidden to enter, and the pole is not allowed to stand vertically below. When hoisting, the operator's energy should be concentrated and obey the command order, and illegal work is strictly prohibited. Lifting operations should be done "five not hanging":

A. The gesture command is unclear and not hanging.

B. The weight is unknown and not hanging.

C. Overload does not hang.

D. The line of sight is not clear.

E. The bundle is not strong or the center of gravity is not clear.

7.9.6 The temporary circuit for construction shall adopt TN-S three-phase five-wire system. The PE wire shall be reliably and repeatedly grounded. The construction machinery and electrical equipment shall not carry sick or overloaded work. If abnormal phenomena are found, it shall be stopped for inspection. Repair in operation.

7.9.7 When building a color steel roof, it is forbidden to wear slippers and bare feet to enter the scene.

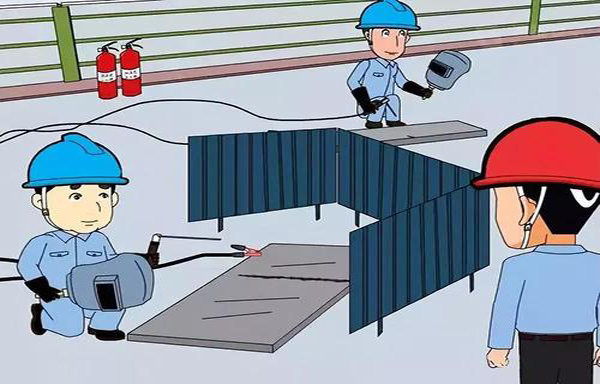

7.9.8 On-site gas cutting and electric welding shall be managed by special personnel and special fire-fighting equipment shall be provided.

7.9.9 All professional trades participating in the installation must obey the unified command on the spot. The responsible person should promptly dissuade the illegal work, and should stop the work immediately if he does not listen to the dissuasion.