Steel structure truss

- 25 Jul 2019

- steel structure

1. Steel roof truss form

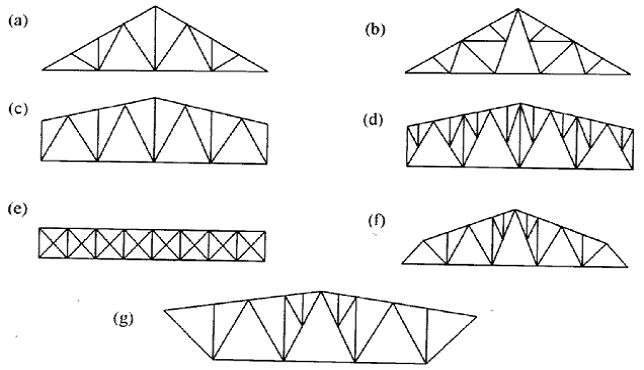

There are many forms of steel structure trusses. The commonly used steel roof trusses mainly include triangular trusses, trapezoidal trusses, parallel truss trusses, and polygonal trusses.

1.1 The triangular roof truss has a large slope (i=1/3~1/2). The upper and lower chords are not evenly loaded, the internal force near the support is large, the span is small, and the length of the web is long. When used for large spans, the triangular truss is not economical. Due to its convenient transportation, it is widely used (Fig. 1-a, 1-b).

1.2 The trapezoidal roof truss can be used for roofs with a slope of less than 1/3, and the internal force of the chord is relatively uniform (Fig. 1-c, 1-d). Trapezoidal roof trusses are widely used in industrial plants.

1.3 Parallel string trusses can be used as brackets in single-slope truss and roof structures (Fig. 1-e).

1.4 The polygonal roof truss has two types: upper winding and lower chord bending. The angle between the upper and lower chords is larger, which makes the internal force of the chord smaller. After the upper chord is bent, the height is raised at the node so that the roof remains on a slope (Fig. 1-f). The lower chord-folded polygonal truss reduces the overall height of the house, but only for houses without hoisting equipment (Figure 1-g).

Figure-1 Roof form

2. Stress characteristics of roof truss members

The upper chord is generally a compression member and is a compression member when there is an inter-node load. The lower chord is a tension member and is a bending member when there is an inter-section load. The web is a shaft tension member or an axial compression rod.

3. Steel roof truss node

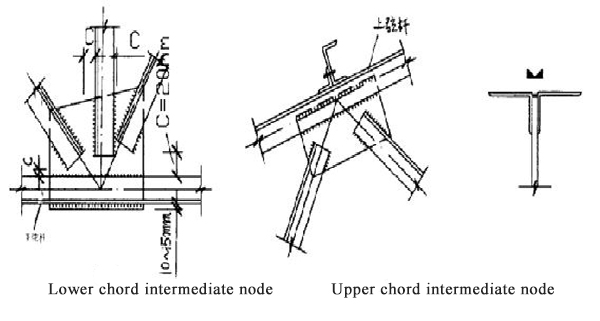

The chord and web of the steel structure roof truss are generally composed of two symmetrical angles, which are integrally joined by joint welding of the gusset plates. At the node, the bar center of gravity should be crossed at a point, and the thickness of the gusset is usually 10~12mm. The clearance C between the chord and the web, the web and the web should not be less than 20mm (not directly subjected to dynamic load) and 50mm (directly subjected to dynamic load), and the clearance between adjacent toe welds should not be less than 5mm. (The welding crane truss is otherwise specified). There are many forms of nodes, and several nodes are described:

3.1 Lower string intermediate node

As shown in Figure 3-1a, the gusset plate is between the two angles of all the bars, and the lower edge extends 10~15mm from the lower leg, and a reasonable gusset shape is determined when the length of the weld and the distance of the member are satisfied. With size.

3.2 Winding intermediate node

When there is a string on the upper string, the gusset plate should be lower than the back of the angle steel to form a groove weld (Fig. 3-1b).

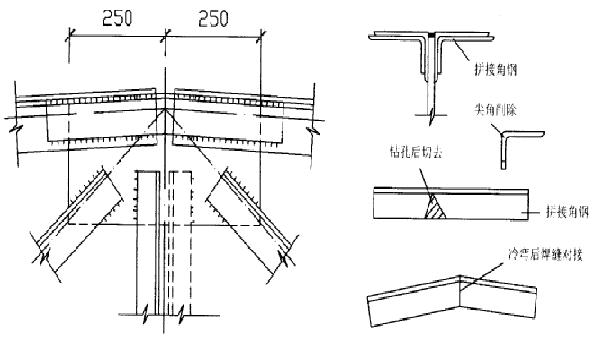

3.3 Roof node

The upper chord is spliced using the same number of angles at the ridge point. In order to make the joint between the angled steel and the upper chord and to facilitate the welding, the corners of the joint angle of the joint angle steel should be removed, and the vertical limbs should be cut into a triangle, and the weld beaded after cold bending (Fig. 3-2).

Figure 3-1 middle node of lower chord and upper chord

Figure 3-2 roof ridge node

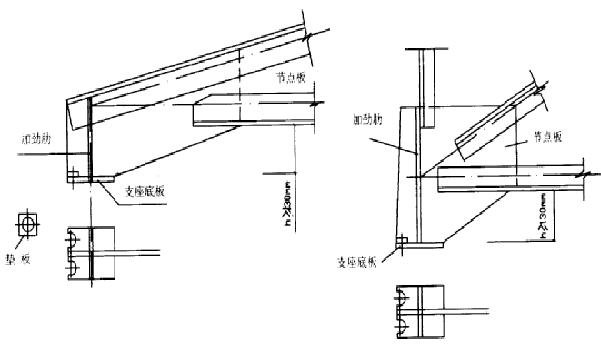

4. Support node

Most of the steel structure truss support nodes are flat-type bearings, which are composed of gusset plates, stiffeners, support plates and anchors. The stiffener is at the center of the support node, and the lower chord is h≥130mm higher than the support base. Figure 4-a is the triangular truss support node, and Figure 4-b is the trapezoidal truss support node.

Figure 4 support nodes

5. Roof support

Support is an indispensable important component in the structure of steel structure roof. Its main function is to increase the spatial rigidity of the steel structure roof structure, ensure the structural geometry and stability, and transmit the horizontal force acting on the roof. According to different parts of the support, there are horizontal horizontal support, lower horizontal horizontal support, lower horizontal vertical support, truss vertical support and tie rod. When there is a skylight, you should also pay attention to the skylight frame support.

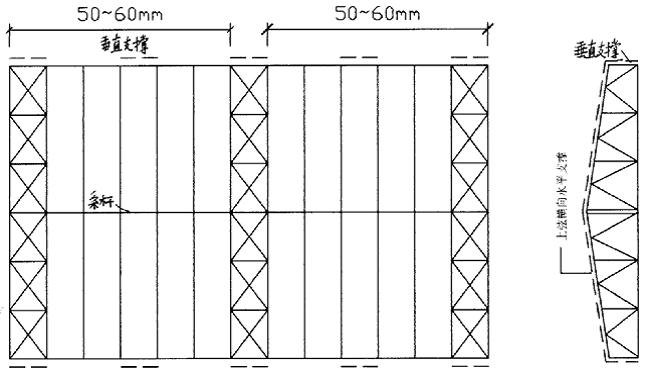

5.1 The horizontal support of the upper string is generally arranged at both ends of the house and between the two sides of the temperature seam. The spacing is controlled at 50~60m, one or more passes are added in the middle of the rear. Located in the oblique plane of the upper chord between the two trusses. When the house is long, add one more for each isolation of 50~60 meters. Its function reduces the length of the upper chord calculation (out-of-plane), and forms a space system with the roof truss to ensure the stability of the chord on the roof truss. (Figure 5-1)

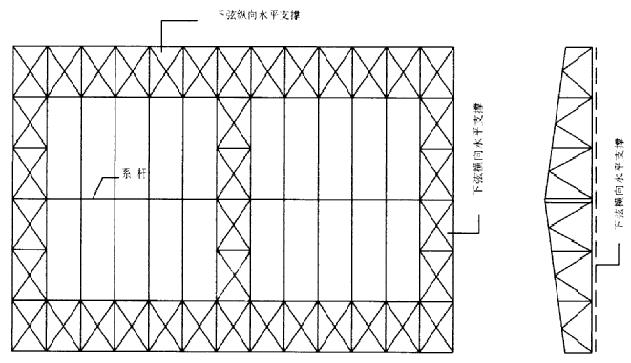

5.2 The lower horizontal horizontal support is generally arranged in the same opening of the horizontal horizontal support of the upper chord. It must be set when the truss of the truss is suspended or the truss bent or the gable wind column is supported by the truss. (Figure 5-2)

5.3 The lower horizontal horizontal support is generally arranged at the two ends of the roof truss, and the horizontal horizontal support of the lower truss of the truss constitutes a closed horizontal support system. Must be set when the plant is vibrating or has a bracket.

5.4 The vertical support of the truss is arranged between the roof trusses and horizontally supported in the same opening direction as the upper and lower strings. It should also be arranged at the support at both ends of the trapezoidal roof truss. When the horizontal horizontal supports are far apart, they can be placed every 4~5 ft. The main function of the vertical support of the roof truss is to ensure the stability of the roof truss and to withstand the longitudinal horizontal forces. The vertical support of the roof truss can be designed as a parallel string truss.

The 5 tie rods are generally arranged between the upper and lower chord nodes of the roof truss and are arranged along the length of the house to ensure the stability of the trusses without lateral support. When there is a stringer or a large roof panel on the truss of the roof truss, the stringing tie is generally no longer provided. The tie rods can be made of angle steel.

Figure 5-1 Upper transverse support

Figure 5-2 Lower chord lateral support