The differences between pir and pur of steel structure

- 03 Jul 2019

- steel structure

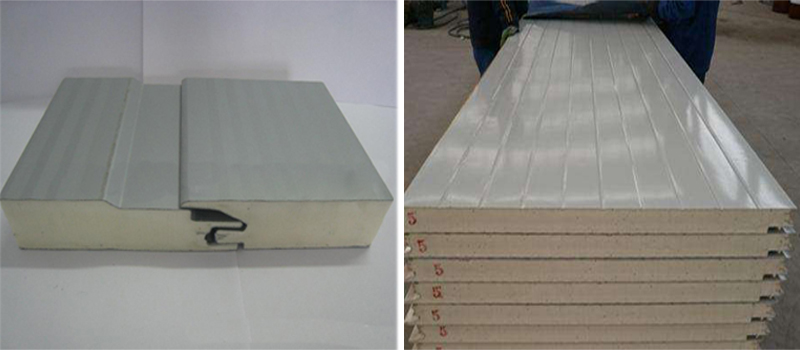

There is an increasing demand for polyurethane sandwich panels in industrial systems now.Many customers are looking for PIR polyurethane sandwich panel and PUR polyurethane sandwich panel as steel structure wall insulation materials recently. What is the difference between PIR and PUR? The so-called PIR polyurethane cold storage board is a polyurethane sandwich panel with a burning grade of B1.

It is necessary to mention the earliest Chinese standard GB8624-1997 "Classification method for burning performance of building materials". This is the earliest standard for building fire protection materials.The description:

Grade A: Non-combustible materials (eg rockwool, stone, etc.)

Grade B1: flame retardant materials (eg polyurethane, polystyrene)

Grade B2: Combustible material (polyurethane, polystyrene)

Grade B3: Flammable materials (extruded polyphenylene, polyurethane, etc.)

Polyurethanes are available in B1, B2, and B3 grades. As the best insulation material today, polyurethane cold storage panels have been widely used in cold storage construction and steel structure food workshops. Polyurethane materials are organic materials, and only inorganic materials can achieve Class A non-combustible. Therefore, the highest combustion grade of polyurethane materials can reach B1.

Both PIR and PUR are one type of polyurethane rigid foam, but there are great differences in chemical and physical properties. Polyurethane rigid foams are mainly composed of polyols and isocyanates. Polyols are further divided into polyether polyols and polyester polyols. The product formed by the reaction of the polyether polyol and the isocyanate is PUR, and the polyester polyol and the isocyanate react to form a polyisocyanurate Peak Information Rate (PIR).

PIR is better than PUR in terms of flame retardancy and low smoke, so it is mainly used for building insulation.The process requirements has high demanding, and the temperature has higher requirements in the production process, but the fluidity is not as good as PUR. PIR is a new type of cryogenic insulation material that can be used in a wide range of pipes and equipment from -196 ° C to +120 ° C, as well as thermal insulation requirements for exterior walls of steel structure. Its thermal conductivity is extremely low, and it has excellent linear expansion coefficient and strength, and is highly resistant to aging.

PUR products are divided into two categories: foamed products and non-foamed products. The foamed products are soft, hard and semi-rigid PUR foam; non-foamed products include paints, adhesives, synthetic leather, elastomers and Elastic fiber, etc.

The fire performance of PIR is better than PUR and the mechanism of fire performance difference:

1. The isocyanate index of the PUR sheet is usually between 110 and 120. The degree of crosslinking in the PUR foam system mainly depends on the functionality of the polyether polyol. However, as the fire rating requirements become more stringent, PUR foams face enormous challenges in meeting fire protection specifications. Usually, to meet the requirements of fire protection regulations, a large amount of flame retardant is added to the formulation system, but at the same time it affects the compressive strength of the foam. And physical properties such as dimensional stability and increase the cost of the product. The cross-linking degree group of the PIR system relies on the excess isocyanate trimerization reaction, usually the isocyanate index reaches 200-300. Under the action of the corresponding catalyst, the excess isocyanate can self-react to form a six-membered ring, which provides cross-linking to the foam collective. It also promotes coking and char formation through its own six-membered ring molecular structure, improving the fire performance of the foam system. In addition, it should be noted that the flame retardant effects of different flame retardants in polyurethane foams vary, and the final effect varies with the content, depending on the compatibility of the flame retardant with the polyurethane foam.

2. The PIR reaction is simple and can use low-cost raw materials;

3. PIR can give the product better high and low temperature dimensional stability, lower thermal decomposition rate, and the combustion process can form a protective carbon layer;

4. The mechanical strength of PIR is better than PUR;

5. The production efficiency of PIR is high.

The shortcomings of PIR relative to PUR:

1. Large brittleness and lower mobility than PUR;

2. Poor adhesion, and the adhesion to the face material is only 1/2 of PUR;

3. PIR has the property of sharp secondary foaming, which will affect the performance of the surface of the sheet;

4. The surface ripening is poor, and the post-maturing is late;

5. The process range is narrow (production temperature is higher than 60 °C), and production is difficult to control. In the production of continuous PIR sheet, the control of the equipment and the external environment is critical to the quality of the final product, and it is necessary to have good temperature control for various chemical raw materials, because this has a great impact on the stability of the entire chemical reaction process and the entire foam molding process.